PAT DS350 Service Manual

- on October 17, 2024

- Categories: News

PAT DS350 Service Manual

The PAT Hirschmann DS350G/GW Load Moment Indicator (LMI) Service Manual provides detailed guidance on maintaining and troubleshooting the PAT DS350G/GW, a Load Moment Indicator designed for hydraulic boom cranes. This manual is essential for understanding the mechanics, electrical components, and various sensor functionalities, all of which ensure the crane's safe and efficient operation.

More Information Here: https://store.bodetechnicalservices.com

PDF Copy Here: PAT DS350G/GW SERVICE MANUAL

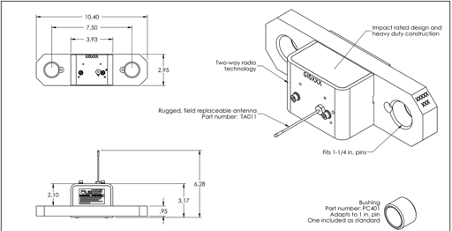

PAT DS350 Mechanical Components

The core components include a pressure transducer, a length-angle transducer, and an anti-two-block switch. The pressure transducer converts hydraulic pressure into an analog voltage signal, which allows the LMI to monitor the crane's load-bearing status. These transducers are installed on the lift cylinder’s rod and piston sides and are connected to the central unit with shielded cables, operating at a supply voltage of ±5V. The length-angle transducer integrates two sensors to measure the boom's length and angle. Housed in the base section, it uses a reeling drum to capture length data and an oil-filled pendulum box to assess the boom angle. Finally, the anti-two-block switch monitors the proximity between the load block and boom head to prevent two-blocking, which could damage the crane by over extension.

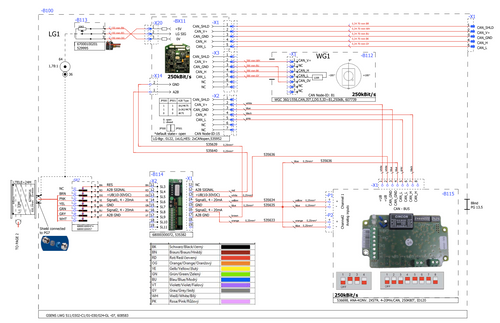

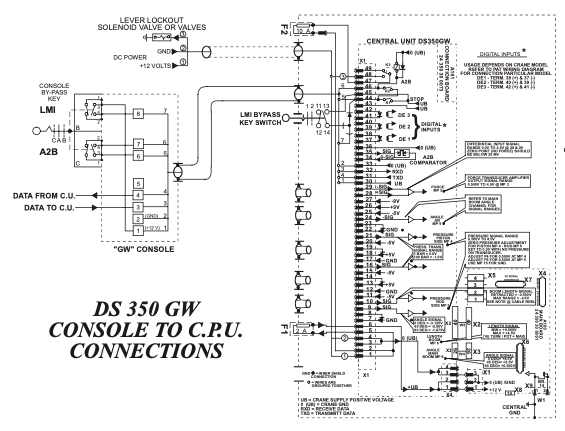

PAT DS350 Central Unit and Console

The central unit is the hub that processes data from all sensors. It features a rugged, waterproof steel casing and houses various fuses for protection. Inside, there are multiple boards for analog-to-digital conversion and data processing. The console is the operator's interface, displaying critical information like boom length, angle, and load capacity. It also includes safety features such as an alarm for overload conditions, a warning light for the anti-two-block condition, and an override switch. A key aspect of the console is its duty-selection switch, which allows configuration for different crane setups, such as lifting over the side or rear. The console’s display helps operators track load limits and working radius in real time, enhancing safety during operations.

PAT DS350G/GW Adjustment and Calibration

The hardware adjustments are vital for the system’s accuracy. Adjustments include tensioning the length cable by rotating the cable reel and fine-tuning the angle sensor for accurate readings. Similarly, pressure channel adjustments ensure the transducers accurately reflect the hydraulic pressures by calibrating them to a baseline voltage when the boom is at rest. This step involves using a voltmeter to achieve precise voltage readings, crucial for maintaining the integrity of the LMI system. These calibration steps are outlined in detail to guide technicians on maintaining the system's accuracy.

PAT DS350 Troubleshooting and Error Codes

The manual offers a comprehensive troubleshooting section, addressing issues like power failure, data transmission errors, and sensor malfunctions. Each error code is documented with specific steps for resolution. For instance, error code E91indicates a loss of data transmission from the console to the central unit, often due to wiring issues or a defective transmitter. Meanwhile, E93 suggests a data transmission problem in the reverse direction. Solutions typically involve checking connections, replacing damaged cables, and ensuring correct voltage levels in the system. The manual includes flowcharts to guide technicians through diagnostics and corrective actions.

The PAT Hirschmann DS350G/GW Service Manual is an essential resource for those responsible for maintaining PAT's LMI systems. By following the detailed instructions and leveraging the troubleshooting guides, technicians can ensure the crane’s LMI system functions safely and effectively, protecting both the equipment and operators.

More Information Here: https://store.bodetechnicalservices.com