Hirschmann Mentor LMI Console for National Boom Truck Crane

- on October 22, 2024

- Categories: News

031-300-060-648 Hirschmann Mentor Console for National Boom Truck Crane

PLEASE NOTE: The Mentor Console LMI does need to be programmed for your specific crane model and serial number. Please contact us directly to confirm your crane calibration software is on file.

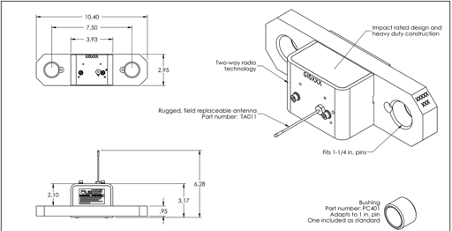

The 031-300-060-648 National Crane Hirschmann Mentor console is a critical component of the Hirschmann Load Moment Indicator (LMI) system, designed to aid crane operators by providing real-time, essential operational data. The console integrates advanced monitoring and control features that enhance crane safety and performance, offering significant benefits to operators and construction companies alike.

PDF Copy of iVisor Mentor Manual HERE

Key Features of the Hirschmann Mentor Console

User-Friendly Interface

The iVisor Hirschmann Mentor console is designed with a large, easy-to-read Liquid Crystal Display (LCD), which provides real-time information to the crane operator. The LCD has a wide temperature range and transflective properties, ensuring visibility in both bright sunlight and low-light conditions. The display automatically adjusts contrast according to surrounding temperatures, allowing operators to work efficiently regardless of environmental conditions. Furthermore, the console is backlit continuously during operation, enhancing visibility during nighttime operations.

Crane Configuration Setup

One of the most important features of the Mentor console is its ability to assist the operator in setting up the crane’s operating configuration. It allows the operator to select the crane's mode, outrigger configuration, hoist, and reeving. The system stores previously used configurations and automatically loads them when needed, saving the operator time and reducing the chance for human error during setup. This interactive process ensures the crane is properly configured before operation begins, reducing the risk of accidents.

Overload and Anti-Two-Block Protection

The Mentor console includes crucial safety features such as load moment limit and prewarning lights. When a crane approaches its rated load capacity, a yellow prewarning light activates, alerting the operator to the approaching limit. Should the crane reach the rated load, a red limit light, along with an audible alarm, is triggered. The system can also disable specific crane functions—such as hoisting up, telescoping out, or booming down—to prevent overloading. Additionally, the Anti-Two-Block (A2B) system warns the operator of a potential over-hoist condition, further safeguarding both the equipment and personnel.

Precise Load Monitoring and Reeving Selection

The console displays critical parameters such as load moment, actual load, capacity, boom length, boom angle, tip height, and reeving configuration (parts-of-line). It allows operators to input the reeving configuration manually and ensures accurate load readings by adjusting the displayed net load. The ability to monitor these parameters in real-time provides operators with the necessary information to make quick decisions while maintaining safety margins.

Limit Settings and Virtual Walls

Another unique feature of the National Crane Mentor console is its ability to set geometric limits for boom angle, radius, and tip height. Operators can define maximum and minimum limits for these parameters, with the system alerting the operator if any of the limits are exceeded. Additionally, the "Virtual Wall" feature allows operators to set a defined working area for the crane, effectively creating a boundary to avoid obstacles like buildings or power lines. The system alerts the operator with visual and audible alarms if the crane approaches or crosses these virtual walls, improving situational awareness.

Alarm Management and Bypass Functionality

The console includes an alarm stop button that allows operators to silence alarms for short durations when necessary. The system is equipped with bypass keys that can override certain functions if required, such as load moment and anti-two-block warnings. These overrides are intended for emergency use and should be applied with caution to prevent dangerous situations.

Benefits of the National Crane Hirschmann iVisor Mentor Console

Enhanced Safety

The Mentor console significantly enhances crane operation safety by providing real-time feedback on critical operating conditions. Its overload protection, anti-two-block warning, and geometric limit settings all help reduce the risk of accidents caused by equipment overload or operator error.

Operational Efficiency

The console’s ability to store previous configurations streamlines the setup process for operators, allowing cranes to be deployed faster and with greater accuracy. This reduces downtime and enhances operational efficiency on the job site.

Operator Confidence

The Mentor console’s clear and comprehensive display of crane parameters allows operators to work with greater confidence, knowing they have full control and awareness of the crane’s operating conditions. The safety alarms and limit-setting features further instill trust in the system’s ability to prevent dangerous situations.

Improved Equipment Longevity

By preventing overloads and dangerous operating conditions, the Mentor console helps reduce wear and tear on the crane, thereby prolonging its service life and minimizing the need for costly repairs.

The iVisor Hirschmann Mentor console is a powerful tool for National crane operators, offering advanced monitoring and control features that enhance both safety and efficiency. Its real-time data display, easy configuration setup, and safety features like overload protection and virtual wall limits make it an indispensable component of modern crane operation.