PAT Hirschmann DS85 Service Manual

- on October 17, 2024

- Categories: News

PAT Hirschmann DS85 Service Manual

The PAT Hirschmann DS85 Service Manual provides detailed instructions and guidance for maintaining and troubleshooting the DS85 Load Moment Indicator (LMI) system, a vital safety feature for crane operations. The DS85 LMI system warns operators of potential overloads and unsafe lifting conditions, enhancing overall crane safety. The manual covers a broad range of topics, from system components and operation principles to specific maintenance procedures and troubleshooting techniques.

MORE INFORMATION HERE: https://store.bodetechnicalservices.com/products/pat-ds85-console

DS85 System Overview

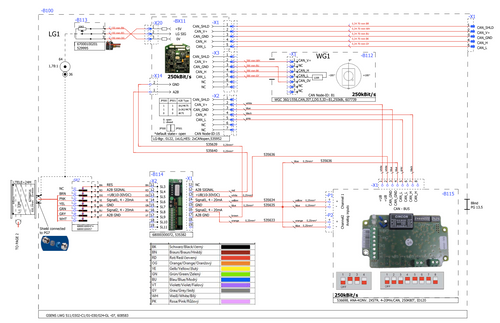

The DS85 system is a CAN-bus-based system that integrates several components, including a central processing unit, pressure transducers, angle sensors, length sensors, and anti-two-block (A2B) devices. The central unit monitors and processes data from the sensors, providing real-time feedback on crane load and movement. This feedback is essential for preventing overloads by stopping certain crane functions if preset load limits are exceeded. The system stores crane-specific data, such as load charts and boom dimensions, in the central processor, which it uses to make calculations based on the actual operating conditions.

PAT Hirschmann DS85 System Components

- Operating Console: Displays information on load, boom angle, length, and crane status. It includes LEDs for operational warnings and an alarm system.

- Pressure Transducers: Measure hydraulic pressure in the lift cylinder, providing data on crane load conditions.

- Angle and Length Sensors: Track boom angle and length through a potentiometer system, delivering precise position data to the console.

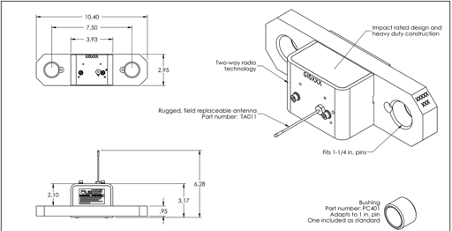

- A2B System: Includes transmitters and receivers that prevent the hook block from hitting the boom, signaling the operator with alarms and locking out certain functions if necessary.

Hirschmann DS85 Key Theories

The manual includes detailed explanations on the theories of angle, length, and pressure measurement:

- Angle Theory: The angle sensor operates through a potentiometer driven by a weighted pendulum, transmitting data digitally via the CAN-bus.

- Length Theory: Length is tracked by a sensor connected to the cable reel; the manual describes steps for ensuring accuracy, including pretensioning and calibration.

- Pressure Theory: Dual transducers on the piston and rod side of the lift cylinder convert hydraulic pressure into electrical signals for load calculations.

PAT DS85 Troubleshooting and Error Codes

The manual lists error codes and troubleshooting steps for common issues with the DS85 system. For example:

- Angle Display Issues: If the displayed angle doesn’t match the actual angle, the angle sensor or CAN-bus converter board may need replacement

- Load Display Discrepancies: A mismatch between displayed and actual load can result from incorrect sensor calibration or faulty pressure transducers.

- A2B System Failures: If the A2B system is malfunctioning, the manual outlines procedures to check power supply, sensor connectivity, and battery status for wireless components.

Hirschmann DS85 Calibration and Maintenance

Regular maintenance and calibration are essential for optimal performance of the DS85 LMI system. The manual includes instructions for:- Sensor Calibration: Guides on zero-setting the transducer inputs and recalibrating length and angle sensors.

- Cable Replacement: Detailed procedures for replacing the cable reel and length sensor, emphasizing the importance of tension and alignment.

- Battery Replacement for Wireless A2B Transmitters: Provides steps to ensure reliable performance of the A2B system’s wireless sensors.

Wika DS85 Safety and Operational Tips

The DS85 LMI system is an aid rather than a substitute for safe crane operation practices. Operators are reminded to perform pre-operation inspections and to follow the proper setup procedures. Accurate system readings depend on correct calibration and daily checks. The manual stresses that crane operators remain responsible for safe crane operation, as the LMI system only assists in warning of potential hazards.This manual is an invaluable resource for maintenance personnel, outlining everything from installation and component identification to advanced troubleshooting techniques. By following the guidance in this manual, users can ensure that the DS85 LMI system functions correctly, enhancing crane safety and preventing equipment damage.

MORE INFORMATION HERE:

https://store.bodetechnicalservices.com/products/pat-ds85-console