Safety Benefits of the Trimble LSI GC012 Load Cell

- on August 26, 2025

- Categories: News

The Safety Benefits of the Trimble LSI GC012 Load Cell

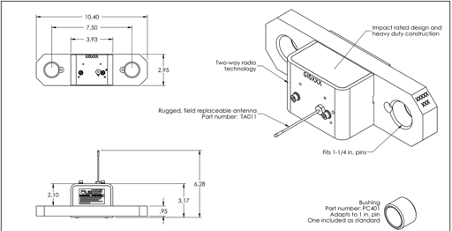

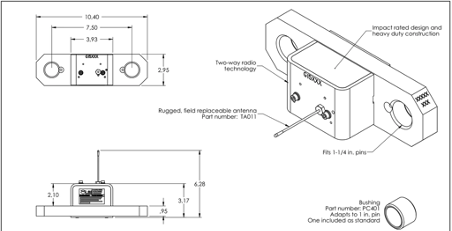

The Trimble GC012 load cell is not simply a measuring device—it is a safety solution designed to protect people, equipment, and businesses. With its unmatched precision, early warning capabilities, rugged durability, and compliance support, the GC012 stands as a critical safeguard in modern crane operations. Investing in the GC012 is more than upgrading technology—it is committing to a culture of safety where every lift is made with confidence and control.

In today’s crane and lifting operations, safety is more than a priority—it is a necessity. Operators, contractors, and equipment owners understand the immense risks involved when handling heavy loads. One mistake can result in costly downtime, damaged equipment, or, worst of all, injuries on the jobsite. That is why the LSI Trimble GC012 load cell has become a critical solution for enhancing safety and ensuring compliance in demanding lifting environments. By providing accurate, real-time load measurement, the GC 012 allows operators to make informed decisions and prevent accidents before they occur.

Precision Load Indication That Protects

The cornerstone of crane safety is accurate load data. The Trimble GC012 load cell delivers high-precision measurements that eliminate guesswork. Unlike older systems that rely on estimations or manual calculations, the GC012 continuously monitors load forces and communicates them directly to the operator. This precision ensures that cranes never exceed rated capacities, significantly reducing the chance of structural overloads, tip-overs, or catastrophic failures.

Accurate load measurement also safeguards against uneven weight distribution, which can put dangerous stress on booms, rigging, and supporting structures. By offering reliable, real-time data, the GC012 allows operators to adjust and correct before these risks escalate.

Early Warning for Safer Crane Operations

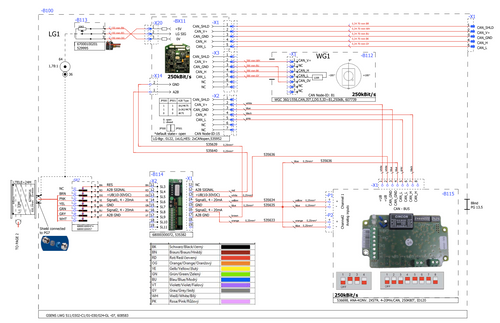

The GC012 is engineered to integrate seamlessly with Trimble GS820 and GS550 crane warning systems. When combined, the system provides early warning alerts for unsafe conditions. If the crane approaches its load limits, the operator receives an immediate signal to take corrective action. This proactive approach helps prevent accidents rather than reacting after an incident has already occurred.

Such early warnings are particularly vital on crowded jobsites, where visibility is limited and multiple crews work in close proximity. With the GC012 monitoring every lift, supervisors gain peace of mind knowing the system is always watching for potential hazards.

Durability Under Demanding Conditions

Cranes and lifting equipment operate in some of the harshest environments—construction sites, shipyards, refineries, and wind farms. The Trimble GC012 load cell is built to withstand these rugged conditions. Its robust design ensures reliable performance even when exposed to extreme temperatures, heavy vibration, or rough handling. This durability guarantees that safety monitoring is never compromised, regardless of the environment.

By minimizing the risk of sensor failures or inaccuracies, the GC012 provides consistent protection throughout the life of the crane, reducing downtime while maximizing operator safety.

Compliance and Risk Reduction

Modern safety regulations require strict adherence to load limits and safe lifting practices. Non-compliance not only increases the likelihood of accidents but also exposes companies to liability, fines, and reputational damage. The Trimble GC012 helps businesses meet OSHA, ANSI, and other global safety standards by ensuring accurate load monitoring at all times.

For contractors and fleet owners, the GC012 is more than a tool—it is insurance. By reducing the risk of accidents, it protects workers, equipment, and investments, while also lowering insurance claims and liability exposure.

Confidence for Operators and Owners

Perhaps the greatest safety benefit of the Trimble GC012 is the confidence it instills in crane operators and equipment owners. Operators can focus on the lift itself rather than worrying about hidden risks, knowing the system is providing precise, real-time load data. Owners, on the other hand, gain assurance that their equipment is being used within safe parameters, reducing wear and extending service life.