Unveiling the Precision of PAT Hirschmann LWG508 Cable Reel: Length Cable Replacement and Adjustment

- on November 27, 2023

- Categories: News

Introduction:

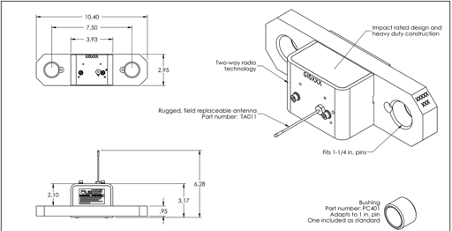

In the world of industrial automation and control systems, precision and reliability are paramount. One such standout component is the PAT Hirschmann LWG508 Cable Reel, a cutting-edge device that plays a crucial role in various applications. In this blog post, we will delve into the intricate details of the PAT Hirschmann LWG508, focusing on its information, length cable replacement, and the nuances of length adjustment.

PAT Hirschmann LWG508 Information:

The PAT Hirschmann LWG508 Cable Reel is a powerhouse in the realm of cable management for industrial machinery. Designed with advanced technology, it ensures seamless and reliable power and signal transmission in demanding environments. Its robust construction and innovative features make it a preferred choice for professionals seeking top-notch performance.

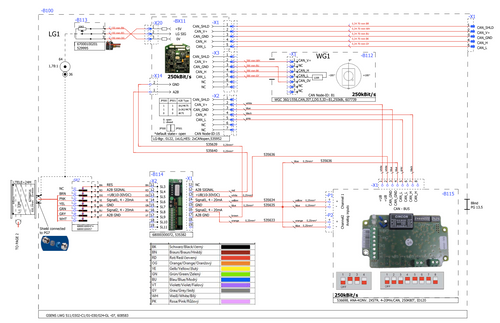

LWG 508 Length Adjustment: Precision in length measurement is crucial for the smooth operation of machinery. The LWG508 excels in this aspect, offering a precise length adjustment mechanism. Here are some key specifications related to length adjustment:

Power Supply Voltage: Both the length and angle transducers operate on a power supply voltage of -5.00V. This ensures a stable power source, contributing to the overall reliability of the cable reel.

Output Signal for Length Transducer: The length transducer provides an output signal ranging from -0.500V to -4.500V. This wide range allows for accurate measurement of cable length, catering to the diverse needs of industrial applications.

Output Signal for Angle Transducer: The angle transducer, another essential component of the LWG508, delivers an output signal between -1.875V and -3.125V. This ensures precise angle measurement, adding an extra layer of accuracy to the cable reel's functionality.

PAT Hirschmann LWG 508 Cable Reel Length Cable Replacement

we will walk you through the step-by-step process of replacing the length cable on the PAT Hirschmann LWG 508 Cable Reel.

Step 1: Safety First

Before you start any maintenance or replacement work, prioritize safety. Ensure that the equipment is powered off, and all energy sources are isolated. Use appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect yourself during the process.

Step 2: Gather Necessary Tools and Equipment

To efficiently replace the length cable, you'll need the following tools and equipment:

Screwdrivers

Wrenches

Replacement cable

Crimping tool

Cable ties

Lubricant (if required)

Step 3: Assess the Cable Reel

Examine the current state of the cable reel. Identify any signs of damage or wear on the existing cable, including cuts, frays, or kinks. This assessment will help you determine the extent of the replacement needed.

Step 4: Detach the Existing Cable

Using the appropriate tools, carefully detach the existing cable from the cable reel. Take note of the cable's route and any connection points. Keep track of how the cable is wound around the reel to replicate the pattern during the replacement.

Step 5: Remove the Cable Drum

In some cases, you may need to remove the cable drum for easier access to the cable and its connection points. Follow the manufacturer's instructions for your specific PAT Hirschmann LWG 508 model to safely remove the drum.

Step 6: Prepare the Replacement Cable

Measure and cut the replacement cable to the required length. Ensure that the new cable is of the same specifications and meets the manufacturer's recommendations. If necessary, crimp connectors onto the cable ends using a crimping tool.

Step 7: Install the Replacement Cable

Thread the replacement cable through the cable reel, following the same path as the original cable. Reattach the cable to any connection points, making sure to secure it properly. If the drum was removed, reassemble it according to the manufacturer's instructions.

Step 8: Test the Cable Reel

Before restoring power to the equipment, perform a thorough test of the cable reel to ensure that the replacement cable is securely in place and functions as intended. Check for any unusual sounds or resistance during rotation.

Step 9: Reapply Lubrication (if necessary)

If your PAT Hirschmann LWG 508 Cable Reel requires lubrication, apply the recommended lubricant to ensure smooth operation. Refer to the manufacturer's guidelines for the appropriate lubrication procedures.

Step 10: Document the Replacement

Keep detailed records of the replacement process, including the date of replacement, the length of the new cable, and any observations made during the procedure. This documentation can be valuable for future maintenance and troubleshooting.

Conclusion: In conclusion, the PAT Hirschmann LWG508 Cable Reel stands out as a reliable and high-performance solution for cable management in industrial settings. Its user-friendly design, coupled with efficient length cable replacement and precise length adjustment features, makes it a go-to choice for professionals who prioritize precision and durability in their operations. Whether you are involved in manufacturing, construction, or any other industry requiring robust cable management solutions, the PAT Hirschmann LWG508 Cable Reel is a name you can trust.