PAT Hirschmann DS350 Replacement

- on May 16, 2024

- Categories: News

The PAT Hirschmann Maestro is an advanced load moment indicator (LMI) system designed to enhance the safety and efficiency of crane operations. Renowned for its cutting-edge technology and user-friendly interface, the Maestro system stands out in the market for its comprehensive features and robust performance. Here are some of its key features:

Advanced Load Monitoring

The Maestro system provides precise load monitoring capabilities, ensuring that operators have real-time information about the load's weight and its position relative to the crane’s capacity. This feature is crucial for preventing overload conditions, which can lead to accidents and equipment damage. The system continuously measures and displays the load, helping operators to make informed decisions. This capability is significantly enhanced compared to earlier models like the PAT DS 350.

User-Friendly Interface

One of the standout features of the PAT Hirschmann Maestro is its intuitive and user-friendly interface. The display is designed to be clear and easy to read, even in challenging working conditions. The touch-screen interface allows for easy navigation through the system's various functions, making it accessible to operators of all experience levels. This ease of use reduces the likelihood of operator error and enhances overall operational efficiency. Users familiar with the PAT DS 350 will appreciate the advanced interface.

Customizable Settings

The Maestro system offers a high degree of customization, allowing operators to tailor the settings to their specific needs. This includes the ability to set custom alarms and warnings based on load limits, boom angles, and other critical parameters. Such customization ensures that the system can be adapted to a wide range of crane types and operational scenarios, providing maximum flexibility and safety. The customizable settings are a significant upgrade from the PAT DS 350, offering more flexibility.

Integrated Data Logging

For enhanced operational oversight, the Maestro system features integrated data logging capabilities. This function records key operational parameters, such as load weights, boom angles, and system alerts. The data can be reviewed and analyzed to improve operational practices, ensure compliance with safety standards, and identify potential areas for improvement. This feature is particularly valuable for fleet managers and safety officers who need to maintain detailed records of crane operations. Unlike the PAT DS 350, the Maestro’s data logging is more advanced and comprehensive.

Enhanced Diagnostics

Replacing the wireless connectivity feature, the Maestro system is equipped with advanced diagnostic capabilities. These features allow for comprehensive system checks and troubleshooting directly from the interface. The diagnostic tools can detect and identify issues with sensors, wiring, and other critical components, providing detailed error codes and suggestions for resolution. Enhanced diagnostics help reduce downtime by enabling quicker identification and repair of faults, ensuring that crane operations can resume promptly and safely. The PAT DS 350 lacked these advanced diagnostic tools, making the Maestro a superior choice.

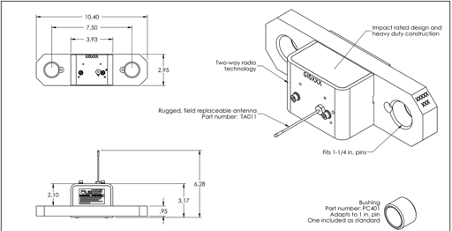

Robust Construction

Built to withstand the rigors of heavy-duty crane operations, the Maestro system features a rugged design. The components are designed to be durable and resistant to harsh environmental conditions, including extreme temperatures, moisture, and dust. This durability ensures that the system remains reliable and accurate, even in the most demanding work environments. The PAT DS 350 was known for its durability, and the Maestro continues this legacy with even more robust construction.

Compliance with Safety Standards

The Maestro system is designed to meet and exceed industry safety standards. It incorporates multiple safety features, such as redundant sensors and fail-safe mechanisms, to ensure reliable operation. By providing accurate and timely information about load conditions, the system helps operators to maintain safe working practices and avoid potentially hazardous situations. The PAT DS 350 set a high standard for safety, which the Maestro exceeds with its advanced features.

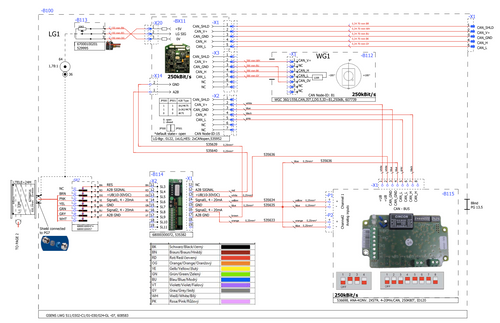

Easy Integration

The PAT Hirschmann Maestro is designed for easy integration with a wide range of crane models. Its flexible architecture allows it to be retrofitted to existing cranes or installed on new equipment with minimal hassle. This ease of integration means that operators can quickly and effectively enhance the safety and efficiency of their crane operations without significant downtime or modification costs. The Maestro’s integration capabilities surpass those of the PAT DS 350, making it a more versatile choice.

Conclusion

In summary, the PAT Hirschmann Maestro is a state-of-the-art load moment indicator system that combines advanced technology with user-friendly features. Its precise load monitoring, customizable settings, integrated data logging, enhanced diagnostics, robust construction, compliance with safety standards, and easy integration make it an invaluable tool for modern crane operations. By enhancing safety and efficiency, the Maestro system represents a significant advancement in crane technology, building on the foundation laid by the PAT DS 350 and pushing the boundaries even further.

Advanced Load Monitoring

The Maestro system provides precise load monitoring capabilities, ensuring that operators have real-time information about the load's weight and its position relative to the crane’s capacity. This feature is crucial for preventing overload conditions, which can lead to accidents and equipment damage. The system continuously measures and displays the load, helping operators to make informed decisions. This capability is significantly enhanced compared to earlier models like the PAT DS 350.

User-Friendly Interface

One of the standout features of the PAT Hirschmann Maestro is its intuitive and user-friendly interface. The display is designed to be clear and easy to read, even in challenging working conditions. The touch-screen interface allows for easy navigation through the system's various functions, making it accessible to operators of all experience levels. This ease of use reduces the likelihood of operator error and enhances overall operational efficiency. Users familiar with the PAT DS 350 will appreciate the advanced interface.

Customizable Settings

The Maestro system offers a high degree of customization, allowing operators to tailor the settings to their specific needs. This includes the ability to set custom alarms and warnings based on load limits, boom angles, and other critical parameters. Such customization ensures that the system can be adapted to a wide range of crane types and operational scenarios, providing maximum flexibility and safety. The customizable settings are a significant upgrade from the PAT DS 350, offering more flexibility.

Integrated Data Logging

For enhanced operational oversight, the Maestro system features integrated data logging capabilities. This function records key operational parameters, such as load weights, boom angles, and system alerts. The data can be reviewed and analyzed to improve operational practices, ensure compliance with safety standards, and identify potential areas for improvement. This feature is particularly valuable for fleet managers and safety officers who need to maintain detailed records of crane operations. Unlike the PAT DS 350, the Maestro’s data logging is more advanced and comprehensive.

Enhanced Diagnostics

Replacing the wireless connectivity feature, the Maestro system is equipped with advanced diagnostic capabilities. These features allow for comprehensive system checks and troubleshooting directly from the interface. The diagnostic tools can detect and identify issues with sensors, wiring, and other critical components, providing detailed error codes and suggestions for resolution. Enhanced diagnostics help reduce downtime by enabling quicker identification and repair of faults, ensuring that crane operations can resume promptly and safely. The PAT DS 350 lacked these advanced diagnostic tools, making the Maestro a superior choice.

Robust Construction

Built to withstand the rigors of heavy-duty crane operations, the Maestro system features a rugged design. The components are designed to be durable and resistant to harsh environmental conditions, including extreme temperatures, moisture, and dust. This durability ensures that the system remains reliable and accurate, even in the most demanding work environments. The PAT DS 350 was known for its durability, and the Maestro continues this legacy with even more robust construction.

Compliance with Safety Standards

The Maestro system is designed to meet and exceed industry safety standards. It incorporates multiple safety features, such as redundant sensors and fail-safe mechanisms, to ensure reliable operation. By providing accurate and timely information about load conditions, the system helps operators to maintain safe working practices and avoid potentially hazardous situations. The PAT DS 350 set a high standard for safety, which the Maestro exceeds with its advanced features.

Easy Integration

The PAT Hirschmann Maestro is designed for easy integration with a wide range of crane models. Its flexible architecture allows it to be retrofitted to existing cranes or installed on new equipment with minimal hassle. This ease of integration means that operators can quickly and effectively enhance the safety and efficiency of their crane operations without significant downtime or modification costs. The Maestro’s integration capabilities surpass those of the PAT DS 350, making it a more versatile choice.

Conclusion

In summary, the PAT Hirschmann Maestro is a state-of-the-art load moment indicator system that combines advanced technology with user-friendly features. Its precise load monitoring, customizable settings, integrated data logging, enhanced diagnostics, robust construction, compliance with safety standards, and easy integration make it an invaluable tool for modern crane operations. By enhancing safety and efficiency, the Maestro system represents a significant advancement in crane technology, building on the foundation laid by the PAT DS 350 and pushing the boundaries even further.