Advantages of the New LMI System in Link Belt LS238H Lattice Crawler Crane

- on March 24, 2024

- Categories: News

Enhancing Efficiency and Safety: The Advantages of the New LMI System in Link Belt LS238H Lattice Crawler Crane

In the realm of heavy machinery, precision, efficiency, and safety stand as paramount pillars of operation. The integration of advanced technology not only enhances these aspects but also revolutionizes the landscape of industrial operations. One such innovation is the introduction of a new Load Moment Indicator (LMI) system in the Link Belt LS238H lattice crawler crane, marking a significant leap forward in construction and lifting capabilities.

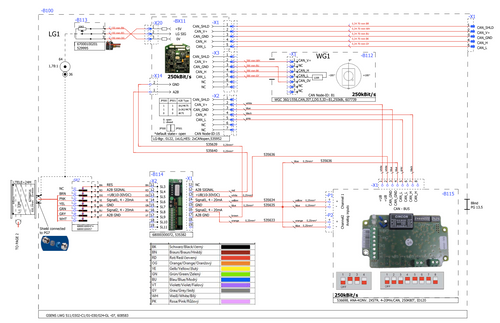

The LMI system serves as the cornerstone of crane operations, providing real-time data crucial for safe and efficient lifting. With the integration of state-of-the-art sensors, algorithms, and interface design, the new LMI system in the LS238H delivers a plethora of benefits that redefine industry standards.

Foremost among these advantages is enhanced safety. Safety remains the top priority in any construction or lifting task, and the LMI system acts as a vigilant guardian, constantly monitoring crucial parameters such as load weight, boom angle, and operational conditions. By providing instant alerts and warnings in case of potential hazards or overloads, the system empowers operators to make informed decisions, mitigating risks and preventing accidents.

Moreover, the new LMI system in the LS238H ensures optimal operational efficiency. By offering precise load calculations and dynamic charts, operators can optimize lift planning, maximizing the crane's capacity while minimizing downtime. This not only streamlines workflow but also contributes to cost savings and project timelines, making it a valuable asset in today's competitive construction industry.

Furthermore, the system's user-friendly interface simplifies operation and training. With intuitive controls and clear displays, even novice operators can quickly familiarize themselves with the crane's functionalities, reducing the learning curve and enhancing overall productivity. Additionally, the system's diagnostic capabilities facilitate proactive maintenance, ensuring that the crane operates at peak performance levels consistently.

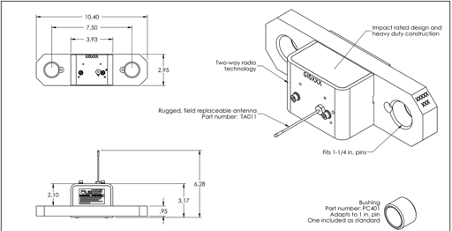

The integration of advanced telemetry and connectivity features further amplifies the benefits of the LMI system. Remote monitoring capabilities allow supervisors and managers to oversee crane operations in real-time, regardless of geographical location. This not only fosters transparency and accountability but also enables swift response to any emerging issues, thereby minimizing disruptions and optimizing resource utilization.

Moreover, the data insights gathered from the LMI system enable informed decision-making and performance analysis. By tracking operational metrics such as load cycles, utilization rates, and fuel consumption, stakeholders can identify areas for improvement, implement targeted optimizations, and ultimately enhance overall operational efficiency and profitability.

Beyond the realm of individual crane operations, the new LMI system in the LS238H contributes to broader industry trends towards digitization and automation. As construction sites embrace technologies such as Building Information Modeling (BIM) and Internet of Things (IoT), the integration of smart crane systems aligns seamlessly with the evolving landscape of smart construction, laying the foundation for interconnected, data-driven workflows that redefine industry norms.

In conclusion, the introduction of the new LMI system in the Link Belt LS238H lattice crawler crane heralds a new era of safety, efficiency, and productivity in lifting operations. By leveraging cutting-edge technology to enhance operational capabilities, this innovative system not only mitigates risks and optimizes performance but also paves the way for a more connected and intelligent construction ecosystem. As industries continue to evolve, investments in advanced crane systems like the LS238H LMI serve as catalysts for progress, driving innovation and unlocking new possibilities in the ever-changing world of heavy machinery.