Lattice Crawer Crane LMI Computer System

-

100% ORIGINAL AND QUALITY

-

24 MONTHS GUARANTEE

-

1-4 DAYS DELIVERY

Lattice Crawler Crane Computer Replacement

Starting at $15,500

Simple - Rugged - Cost Effective

Computer System for Lattice Crawler Cranes

GET A QUOTE

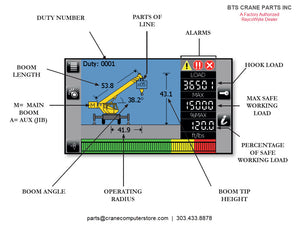

This lattice crawler crane RCI computer replacement system has been developed to meet global regulations and standards. Whether the computer is used for a simple or complex application, it maintains simple display of information with user intuitive menus for easy operation.

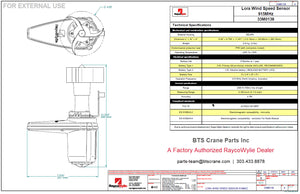

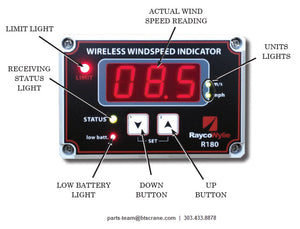

The i4500 lattice crane computer replacement system is one of the first systems in the world capable of utilizing both wired and wireless sensors in the same network The i4500 LMI computer is a computerized crane monitoring system designed to help the operator to safely operate the crane and to respect the maximum load authorized by the crane manufacturer.

The i4500 monitoring system automatically monitors the load lifted by the crane and constantly compares it with the maximum load allowed for each position. The display of the system allows the operator to see continuous information related to the actual load lifted by the crane. It also warns the operator when he approaches the limit or goes over the capacity of the crane.

The system has sensors installed on the machine in order to measure or verify:

- The boom angle

- The hook load

- The two block condition

The lattice crane computer system takes this information to check overload conditions and to measure the operating radius and the crane capacity. A slew sensor (optional) can also be installed to measure the boom position (on 360 degrees) and give extra information to the operator. The display is located inside the operator’s cab to provide an easy access to the information. All the sensors are linked through a CAN bus network (Controlled Area Network).

The actual load is expressed as a percentage of the permitted load (maximum load or safe working load - % SWL). If this percentage exceeds a preset value, alarms and safety functions are activated. The required crane duty charts are stored in a non-volatile memory and can only be modified with the approval of the crane manufacturer. The calculated crane parameters and calibration data are stored in an additional non-volatile memory.

The i4500 display in this lattice crane LMI computer system has been developed to meet the ever demanding regulations and standards of the crane and lifting industry while maintaining simple, clear information for the operator.

GET A QUOTE

Using a full color display in 4.3” screen size means there is always an option to suit your requirements. This coupled with self-diagnostics, operator usability, and ease of calibration keeps the i4500 series ahead of the competition. The systems use the CAN bus J1939 protocol to communicate with each interface, constantly monitoring all the cranes sensors to give clear accurate information to the operator, the CAN bus network also allows huge amounts of flexibility allowing you to add or remove sensors when required at any time throughout the life of the equipment.

This lattice crawler RCI Computer replacement system has been developed with your crane in mind, please reach out to us for a complete quote for your system.

Lattice Crawler Crane Computer Replacement

Starting at $15,500

Simple - Rugged - Cost Effective

Computer System for Lattice Crawler Cranes

GET A QUOTE

This lattice crawler crane RCI computer replacement system has been developed to meet global regulations and standards. Whether the computer is used for a simple or complex application, it maintains simple display of information with user intuitive menus for easy operation.

The i4500 lattice crane computer replacement system is one of the first systems in the world capable of utilizing both wired and wireless sensors in the same network The i4500 LMI computer is a computerized crane monitoring system designed to help the operator to safely operate the crane and to respect the maximum load authorized by the crane manufacturer.

The i4500 monitoring system automatically monitors the load lifted by the crane and constantly compares it with the maximum load allowed for each position. The display of the system allows the operator to see continuous information related to the actual load lifted by the crane. It also warns the operator when he approaches the limit or goes over the capacity of the crane.

The system has sensors installed on the machine in order to measure or verify:

- The boom angle

- The hook load

- The two block condition

The lattice crane computer system takes this information to check overload conditions and to measure the operating radius and the crane capacity. A slew sensor (optional) can also be installed to measure the boom position (on 360 degrees) and give extra information to the operator. The display is located inside the operator’s cab to provide an easy access to the information. All the sensors are linked through a CAN bus network (Controlled Area Network).

The actual load is expressed as a percentage of the permitted load (maximum load or safe working load - % SWL). If this percentage exceeds a preset value, alarms and safety functions are activated. The required crane duty charts are stored in a non-volatile memory and can only be modified with the approval of the crane manufacturer. The calculated crane parameters and calibration data are stored in an additional non-volatile memory.

The i4500 display in this lattice crane LMI computer system has been developed to meet the ever demanding regulations and standards of the crane and lifting industry while maintaining simple, clear information for the operator.

GET A QUOTE

Using a full color display in 4.3” screen size means there is always an option to suit your requirements. This coupled with self-diagnostics, operator usability, and ease of calibration keeps the i4500 series ahead of the competition. The systems use the CAN bus J1939 protocol to communicate with each interface, constantly monitoring all the cranes sensors to give clear accurate information to the operator, the CAN bus network also allows huge amounts of flexibility allowing you to add or remove sensors when required at any time throughout the life of the equipment.

This lattice crawler RCI Computer replacement system has been developed with your crane in mind, please reach out to us for a complete quote for your system.

Have a Question?

The BTS Parts Team is always available to answer any questions you may have. Please feel free to leave a message and we will reply within 24 hours.

4737 North Ocean Drive

Suite 206

Fort Lauderdale FL 33308