- BTS Crane Parts StoreHome

- Featured Products

- Hirschmann

Featured Products

Filter

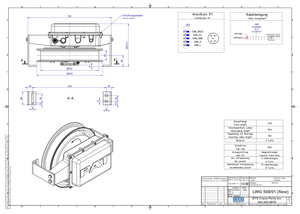

{"id":7968821051559,"title":"Grove 9333103873 LWG508 Cable Reel","handle":"grove-068-508-060-001-lwg508-cable-reel","description":"\u003cp\u003eORIGINAL EQUIPMENT - Grove 9333103873 LWG508 Cable Reel with length and angle transmission. \u003cbr\u003e\u003c\/p\u003e\n\u003cp\u003eGrove 9333103873 LWG508: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip. \u003c\/p\u003e\n\u003ch1\u003e PAT Hirschmann LWG508 ID Tag\u003cbr\u003e\n\u003c\/h1\u003e\n\u003cp\u003e\u003cimg style=\"display: block; margin-left: auto; margin-right: auto;\" height=\"352\" width=\"535\" src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/PATHirschmannLWG508CableReelTag.jpg?v=1699987369\" alt=\"PAT Hirschmann LWG508 Cable Reel\"\u003e\u003c\/p\u003e\n\u003cp\u003e\u003cbr\u003e\u003c\/p\u003e\n\u003cp\u003eA reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.\u003c\/p\u003e\n\u003cp\u003e\u003cbr\u003e\u003c\/p\u003e\n\u003ch2\u003eGrove 9333103873 LWG508 Cable Reel Schematic\u003c\/h2\u003e\n\u003cp\u003e\u003cimg alt=\"\" src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/PATHirschmannLWG508CableReelSchematic.jpg?v=1699987304\"\u003e\u003c\/p\u003e\n\u003ch3\u003eGrove 9333103873 LWG508 Cable Reel Information\u003cbr\u003e\n\u003c\/h3\u003e\n\u003cp\u003eThe Length-Angle Transducer: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip. \u003c\/p\u003e\n\u003cp\u003eA reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.\u003c\/p\u003e\n\u003cul\u003e\n\u003cli\u003eThe power supply voltage for both is -5.00V\u003c\/li\u003e\n\u003cli\u003eThe output signal for the length transducer is: -0.500V up to -4.500V\u003c\/li\u003e\n\u003cli\u003eThe output signal for the angle transducer is: -1.875V up to -3.125V\u003c\/li\u003e\n\u003c\/ul\u003e\n\u003cp\u003eLWG 508 Length Adjustment: Ensure that the length cable tension is correct with fully retracted boom by turning the cable reel 5 to 8 turns counterclockwise. Then remove cover form LWG and adjust counterclockwise the potentiometer to end stop.\u003c\/p\u003e\n\u003ch2\u003eGrove 9333103873 LWG508 Cable Reel Replacement\u003cbr\u003e\n\u003c\/h2\u003e\n\u003col\u003e\n\u003cli\u003eCut old cable at cable drum\u003c\/li\u003e\n\u003cli\u003eDisconnect damaged length cable from junction box at the boom nose.\u003c\/li\u003e\n\u003cli\u003eOpen cable reel cover and disconnect wiring from connection block. Pull 7 conductor cable out of strain relief.\u003c\/li\u003e\n\u003cli\u003eRemove cable reel from mounting brackets.\u003c\/li\u003e\n\u003cli\u003eRemove damaged length cable, which is mounted to the slip rings in the cable reel, from slipring connection. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eOn the back side of the cable reel, open the strain relief attached to the axle in the center of the drum. Pull existing length cable out of the cable reel.\u003c\/li\u003e\n\u003cli\u003ePull new length cable through the hole, pipe and strain relief and push it through the axle of the reeling drum. Tighten strain relief to ensure sealing.\u003c\/li\u003e\n\u003cli\u003eReconnect the length cable to the slipring. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eRemount cable reel to the boom.\u003c\/li\u003e\n\u003cli\u003eTurn reeling drum clockwise to spool the new cable neatly onto the drum.\u003c\/li\u003e\n\u003cli\u003eSet preload on cable reel by turning the drum counter-clockwise 5 to 8 turns.\u003c\/li\u003e\n\u003cli\u003eWrap the new length cable around the boom tip anchor pin (4 or 5 wraps) and secure with tie wraps. Leave enough length cable to connect into the boom tip junction box.\u003c\/li\u003e\n\u003cli\u003eConnect the length cable into the boom tip junction box.\u003c\/li\u003e\n\u003cli\u003eReset length potentiometer in length angle transducer (screw is located in center of white gear); with boom fully retracted, turn potentiometer carefully counter-clockwise until it stops. Recheck length and angle display. \u003cbr\u003e\n\u003c\/li\u003e\n\u003c\/ol\u003e\n\u003cp\u003e\u003cbr\u003e\u003c\/p\u003e\n\u003cp\u003e\u003cbr\u003e\u003c\/p\u003e\n\u003cp\u003e\u003cbr\u003e\u003c\/p\u003e","published_at":"2024-03-12T03:24:38-04:00","created_at":"2024-03-12T03:21:38-04:00","vendor":"PAT HIRSCHMANN","type":"CABLE REEL","tags":["Cable Reel","Hirschmann","LWG508","PAT"],"price":525900,"price_min":525900,"price_max":525900,"available":true,"price_varies":false,"compare_at_price":587200,"compare_at_price_min":587200,"compare_at_price_max":587200,"compare_at_price_varies":false,"variants":[{"id":44842808213671,"title":"Default Title","option1":"Default Title","option2":null,"option3":null,"sku":"068-508-060-001","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"Grove 9333103873 LWG508 Cable Reel","public_title":null,"options":["Default Title"],"price":525900,"weight":41277,"compare_at_price":587200,"inventory_quantity":-1,"inventory_management":"shopify","inventory_policy":"continue","barcode":null,"requires_selling_plan":false,"selling_plan_allocations":[]}],"images":["\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PAT-Hirschmann-Cable-Reel_f0eac1e9-6db8-4113-a3c2-344f5b80bf7b.jpg?v=1710228100"],"featured_image":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PAT-Hirschmann-Cable-Reel_f0eac1e9-6db8-4113-a3c2-344f5b80bf7b.jpg?v=1710228100","options":["Title"],"media":[{"alt":null,"id":28684356780199,"position":1,"preview_image":{"aspect_ratio":1.368,"height":467,"width":639,"src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PAT-Hirschmann-Cable-Reel_f0eac1e9-6db8-4113-a3c2-344f5b80bf7b.jpg?v=1710228100"},"aspect_ratio":1.368,"height":467,"media_type":"image","src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PAT-Hirschmann-Cable-Reel_f0eac1e9-6db8-4113-a3c2-344f5b80bf7b.jpg?v=1710228100","width":639}],"requires_selling_plan":false,"selling_plan_groups":[],"content":"\u003cp\u003eORIGINAL EQUIPMENT - Grove 9333103873 LWG508 Cable Reel with length and angle transmission. \u003cbr\u003e\u003c\/p\u003e\n\u003cp\u003eGrove 9333103873 LWG508: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip. \u003c\/p\u003e\n\u003ch1\u003e PAT Hirschmann LWG508 ID Tag\u003cbr\u003e\n\u003c\/h1\u003e\n\u003cp\u003e\u003cimg style=\"display: block; margin-left: auto; margin-right: auto;\" height=\"352\" width=\"535\" src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/PATHirschmannLWG508CableReelTag.jpg?v=1699987369\" alt=\"PAT Hirschmann LWG508 Cable Reel\"\u003e\u003c\/p\u003e\n\u003cp\u003e\u003cbr\u003e\u003c\/p\u003e\n\u003cp\u003eA reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.\u003c\/p\u003e\n\u003cp\u003e\u003cbr\u003e\u003c\/p\u003e\n\u003ch2\u003eGrove 9333103873 LWG508 Cable Reel Schematic\u003c\/h2\u003e\n\u003cp\u003e\u003cimg alt=\"\" src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/PATHirschmannLWG508CableReelSchematic.jpg?v=1699987304\"\u003e\u003c\/p\u003e\n\u003ch3\u003eGrove 9333103873 LWG508 Cable Reel Information\u003cbr\u003e\n\u003c\/h3\u003e\n\u003cp\u003eThe Length-Angle Transducer: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip. \u003c\/p\u003e\n\u003cp\u003eA reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.\u003c\/p\u003e\n\u003cul\u003e\n\u003cli\u003eThe power supply voltage for both is -5.00V\u003c\/li\u003e\n\u003cli\u003eThe output signal for the length transducer is: -0.500V up to -4.500V\u003c\/li\u003e\n\u003cli\u003eThe output signal for the angle transducer is: -1.875V up to -3.125V\u003c\/li\u003e\n\u003c\/ul\u003e\n\u003cp\u003eLWG 508 Length Adjustment: Ensure that the length cable tension is correct with fully retracted boom by turning the cable reel 5 to 8 turns counterclockwise. Then remove cover form LWG and adjust counterclockwise the potentiometer to end stop.\u003c\/p\u003e\n\u003ch2\u003eGrove 9333103873 LWG508 Cable Reel Replacement\u003cbr\u003e\n\u003c\/h2\u003e\n\u003col\u003e\n\u003cli\u003eCut old cable at cable drum\u003c\/li\u003e\n\u003cli\u003eDisconnect damaged length cable from junction box at the boom nose.\u003c\/li\u003e\n\u003cli\u003eOpen cable reel cover and disconnect wiring from connection block. Pull 7 conductor cable out of strain relief.\u003c\/li\u003e\n\u003cli\u003eRemove cable reel from mounting brackets.\u003c\/li\u003e\n\u003cli\u003eRemove damaged length cable, which is mounted to the slip rings in the cable reel, from slipring connection. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eOn the back side of the cable reel, open the strain relief attached to the axle in the center of the drum. Pull existing length cable out of the cable reel.\u003c\/li\u003e\n\u003cli\u003ePull new length cable through the hole, pipe and strain relief and push it through the axle of the reeling drum. Tighten strain relief to ensure sealing.\u003c\/li\u003e\n\u003cli\u003eReconnect the length cable to the slipring. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eRemount cable reel to the boom.\u003c\/li\u003e\n\u003cli\u003eTurn reeling drum clockwise to spool the new cable neatly onto the drum.\u003c\/li\u003e\n\u003cli\u003eSet preload on cable reel by turning the drum counter-clockwise 5 to 8 turns.\u003c\/li\u003e\n\u003cli\u003eWrap the new length cable around the boom tip anchor pin (4 or 5 wraps) and secure with tie wraps. Leave enough length cable to connect into the boom tip junction box.\u003c\/li\u003e\n\u003cli\u003eConnect the length cable into the boom tip junction box.\u003c\/li\u003e\n\u003cli\u003eReset length potentiometer in length angle transducer (screw is located in center of white gear); with boom fully retracted, turn potentiometer carefully counter-clockwise until it stops. Recheck length and angle display. \u003cbr\u003e\n\u003c\/li\u003e\n\u003c\/ol\u003e\n\u003cp\u003e\u003cbr\u003e\u003c\/p\u003e\n\u003cp\u003e\u003cbr\u003e\u003c\/p\u003e\n\u003cp\u003e\u003cbr\u003e\u003c\/p\u003e"}

PAT HIRSCHMANN

Grove 9333103873 LWG508 Cable Reel

$ 5,259.00

$ 5,872.00

{"id":4745108100,"title":"Hirschmann Maestro PAT DS350 \u0026 DS50 Upgrade Kit","handle":"hirschmann-maestro-ds350-ds50-upgrade-kit","description":"\u003ch1\u003ePAT DS350 \/ DS150 Upgrade Kit \u003cbr\u003e\n\u003c\/h1\u003e\n\u003cul\u003e\u003c\/ul\u003e\n\u003cp\u003eThe WIKA QScale Maestro is an advanced load moment indicator (LMI) system designed to upgrade aging PAT DS350 or DS150 LMI systems by enhance crane safety and operational efficiency. Known for its innovative technology and user-friendly interface, the QScale Maestro offers a range of features and benefits that make it an invaluable tool for crane operators.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e\u003cspan style=\"line-height: 1.4; font-size: 15px;\"\u003eMaestro Features\u003c\/span\u003e\u003c\/strong\u003e\u003c\/p\u003e\n\u003cul\u003e\n\u003cli\u003eUpgrades PAT DS350G \/ GW, DS150, and older Maestro Systems\u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eConverts existing software\/No re-calibration required\u003c\/li\u003e\n\u003cli\u003eMinimal setup through user-friendly console\u003c\/li\u003e\n\u003cli\u003eDisplays actual and allowable load, boom length, boom angle, and load radius\u003c\/li\u003e\n\u003cli\u003eLarger display for improved visibility\u003c\/li\u003e\n\u003cli\u003eIntegrated bargraph provides a quick reference of the cranes utilization\u003c\/li\u003e\n\u003cli\u003eDisplays actual and allowable load, boom length, boom angle \u0026amp; load radius\u003c\/li\u003e\n\u003cli\u003eIntegrated light-bar and event recorder\u003c\/li\u003e\n\u003cli\u003eOptional external light-tower feature\u003c\/li\u003e\n\u003cli\u003evSCALE D2 console with 4.3“ color display\u003c\/li\u003e\n\u003cli\u003eOperating temperature: -40°C to +70°C\u003c\/li\u003e\n\u003cli\u003eProtection class: IP66\/67\u003c\/li\u003e\n\u003c\/ul\u003e\n\u003cp\u003e\u003cstrong\u003e Maestro Retrofit in Four Easy Steps\u003c\/strong\u003e\u003c\/p\u003e\n\u003cul\u003e\n\u003cli\u003eMount and install your brand new central unit, console and new pressure transducers\u003c\/li\u003e\n\u003cli\u003eInstall memory chips from the old system in your new maestro central unit. Note software may be a separate cost. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eAdjust the sensors quickly and simply by using the keyboard from the maestro console. Note cable reel may need upgrade kit to function. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eFinish by performing a test run.\u003c\/li\u003e\n\u003cli\u003eThat’s it! The crane is now ready to use.\u003c\/li\u003e\n\u003c\/ul\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp\u003e\u003ca href=\"http:\/\/bodetechnicalservices.com\/pat-hirschmann-maestro\/\" title=\"Hirschmann Maestro Information\" target=\"_blank\"\u003e\u003cspan style=\"line-height: 1.4; font-size: 15px;\"\u003eClick Here for Brochures \u0026amp; Information\u003c\/span\u003e\u003c\/a\u003e\u003c\/p\u003e\n\u003cp\u003e\u003ca href=\"http:\/\/bodetechnicalservices.com\/pat-hirschmann-maestro-installation-manual-guide\/\" title=\"Hirschmann Maestro Installation\" target=\"_blank\"\u003e\u003cspan style=\"line-height: 1.4; font-size: 15px;\"\u003eClick Here for Sample Installation \u003c\/span\u003e\u003c\/a\u003e\u003c\/p\u003e\n\u003cul\u003e\u003c\/ul\u003e\n\u003cul\u003e\u003c\/ul\u003e\n\u003cdiv class=\"flex flex-grow flex-col max-w-full\"\u003e\n\u003cdiv class=\"min-h-[20px] text-message flex flex-col items-start whitespace-pre-wrap break-words [.text-message+\u0026amp;]:mt-5 juice:w-full juice:items-end overflow-x-auto gap-2\" dir=\"auto\" data-message-id=\"28111606-77df-498e-a100-914bb42af4fc\" data-message-author-role=\"assistant\"\u003e\n\u003cdiv class=\"flex w-full flex-col gap-1 juice:empty:hidden juice:first:pt-[3px]\"\u003e\n\u003cdiv class=\"markdown prose w-full break-words dark:prose-invert light\"\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003ch3\u003eKey Features\u003c\/h3\u003e\n\u003cp\u003e\u003cstrong\u003e1. Precise Load Monitoring:\u003c\/strong\u003e The QScale Maestro provides accurate, real-time information about load weights and their positions relative to the crane's capacity. This feature helps prevent overloading, reducing the risk of accidents and equipment damage.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e2. User-Friendly Interface:\u003c\/strong\u003e The system boasts a clear, easy-to-read display with a touch-screen interface, making it accessible for operators of all experience levels. This intuitive design minimizes operator error and enhances productivity.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e3. Customizable Settings:\u003c\/strong\u003e Operators can tailor alarms and warnings based on specific load limits, boom angles, and other critical parameters. This flexibility ensures the system can adapt to various crane types and operational scenarios.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e4. Integrated Data Logging:\u003c\/strong\u003e The QScale Maestro records key operational data such as load weights and system alerts. This information can be reviewed to improve operational practices, ensure safety compliance, and identify areas for improvement.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e5. Robust Construction:\u003c\/strong\u003e Designed for heavy-duty use, the QScale Maestro is durable and resistant to extreme environmental conditions, including temperature fluctuations, moisture, and dust.\u003c\/p\u003e\n\u003ch3\u003eBenefits\u003c\/h3\u003e\n\u003cp\u003e\u003cstrong\u003eEnhanced Safety:\u003c\/strong\u003e By providing precise load information and customizable warnings, the QScale Maestro helps maintain safe working practices.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eImproved Efficiency:\u003c\/strong\u003e The user-friendly interface and real-time data access allow operators to work more efficiently and make informed decisions quickly.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eReliability:\u003c\/strong\u003e The robust construction and integrated diagnostics ensure long-term reliability, reducing downtime and maintenance costs.\u003c\/p\u003e\n\u003cp\u003eIn summary, the WIKA QScale Maestro is a cutting-edge LMI system that significantly enhances crane safety and efficiency, making it an essential asset for modern crane operations.\u003c\/p\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp style=\"text-align: center;\"\u003e\u003cimg src=\"\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/BTS_Social_Proof_Narrow_398e8837-6873-4848-8a8e-26b11b44b295.png?v=1519189255\" alt=\"\"\u003e\u003c\/p\u003e\n\u003cp\u003e \u003c\/p\u003e","published_at":"2018-06-15T07:07:25-04:00","created_at":"2016-04-08T15:26:39-04:00","vendor":"PAT HIRSCHMANN","type":"","tags":["complete LMI replacement","Display","Hirschmann","PAT","WIKA"],"price":989800,"price_min":989800,"price_max":989800,"available":true,"price_varies":false,"compare_at_price":null,"compare_at_price_min":0,"compare_at_price_max":0,"compare_at_price_varies":false,"variants":[{"id":17580966148,"title":"Default Title","option1":"Default Title","option2":null,"option3":null,"sku":"qScale","requires_shipping":true,"taxable":false,"featured_image":null,"available":true,"name":"Hirschmann Maestro PAT DS350 \u0026 DS50 Upgrade Kit","public_title":null,"options":["Default Title"],"price":989800,"weight":24948,"compare_at_price":null,"inventory_quantity":2,"inventory_management":"shopify","inventory_policy":"deny","barcode":"","requires_selling_plan":false,"selling_plan_allocations":[]}],"images":["\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/WIKAqScaleMaestroUpgradeKit.jpg?v=1715883429","\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PATHirschmannDS350Replacement_d0ce4fad-951a-4242-a872-6d380fd9417b.png?v=1715883429"],"featured_image":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/WIKAqScaleMaestroUpgradeKit.jpg?v=1715883429","options":["Title"],"media":[{"alt":null,"id":29209781305511,"position":1,"preview_image":{"aspect_ratio":1.375,"height":1355,"width":1863,"src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/WIKAqScaleMaestroUpgradeKit.jpg?v=1715883429"},"aspect_ratio":1.375,"height":1355,"media_type":"image","src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/WIKAqScaleMaestroUpgradeKit.jpg?v=1715883429","width":1863},{"alt":null,"id":29209404833959,"position":2,"preview_image":{"aspect_ratio":1.502,"height":233,"width":350,"src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PATHirschmannDS350Replacement_d0ce4fad-951a-4242-a872-6d380fd9417b.png?v=1715883429"},"aspect_ratio":1.502,"height":233,"media_type":"image","src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PATHirschmannDS350Replacement_d0ce4fad-951a-4242-a872-6d380fd9417b.png?v=1715883429","width":350}],"requires_selling_plan":false,"selling_plan_groups":[],"content":"\u003ch1\u003ePAT DS350 \/ DS150 Upgrade Kit \u003cbr\u003e\n\u003c\/h1\u003e\n\u003cul\u003e\u003c\/ul\u003e\n\u003cp\u003eThe WIKA QScale Maestro is an advanced load moment indicator (LMI) system designed to upgrade aging PAT DS350 or DS150 LMI systems by enhance crane safety and operational efficiency. Known for its innovative technology and user-friendly interface, the QScale Maestro offers a range of features and benefits that make it an invaluable tool for crane operators.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e\u003cspan style=\"line-height: 1.4; font-size: 15px;\"\u003eMaestro Features\u003c\/span\u003e\u003c\/strong\u003e\u003c\/p\u003e\n\u003cul\u003e\n\u003cli\u003eUpgrades PAT DS350G \/ GW, DS150, and older Maestro Systems\u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eConverts existing software\/No re-calibration required\u003c\/li\u003e\n\u003cli\u003eMinimal setup through user-friendly console\u003c\/li\u003e\n\u003cli\u003eDisplays actual and allowable load, boom length, boom angle, and load radius\u003c\/li\u003e\n\u003cli\u003eLarger display for improved visibility\u003c\/li\u003e\n\u003cli\u003eIntegrated bargraph provides a quick reference of the cranes utilization\u003c\/li\u003e\n\u003cli\u003eDisplays actual and allowable load, boom length, boom angle \u0026amp; load radius\u003c\/li\u003e\n\u003cli\u003eIntegrated light-bar and event recorder\u003c\/li\u003e\n\u003cli\u003eOptional external light-tower feature\u003c\/li\u003e\n\u003cli\u003evSCALE D2 console with 4.3“ color display\u003c\/li\u003e\n\u003cli\u003eOperating temperature: -40°C to +70°C\u003c\/li\u003e\n\u003cli\u003eProtection class: IP66\/67\u003c\/li\u003e\n\u003c\/ul\u003e\n\u003cp\u003e\u003cstrong\u003e Maestro Retrofit in Four Easy Steps\u003c\/strong\u003e\u003c\/p\u003e\n\u003cul\u003e\n\u003cli\u003eMount and install your brand new central unit, console and new pressure transducers\u003c\/li\u003e\n\u003cli\u003eInstall memory chips from the old system in your new maestro central unit. Note software may be a separate cost. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eAdjust the sensors quickly and simply by using the keyboard from the maestro console. Note cable reel may need upgrade kit to function. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eFinish by performing a test run.\u003c\/li\u003e\n\u003cli\u003eThat’s it! The crane is now ready to use.\u003c\/li\u003e\n\u003c\/ul\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp\u003e\u003ca href=\"http:\/\/bodetechnicalservices.com\/pat-hirschmann-maestro\/\" title=\"Hirschmann Maestro Information\" target=\"_blank\"\u003e\u003cspan style=\"line-height: 1.4; font-size: 15px;\"\u003eClick Here for Brochures \u0026amp; Information\u003c\/span\u003e\u003c\/a\u003e\u003c\/p\u003e\n\u003cp\u003e\u003ca href=\"http:\/\/bodetechnicalservices.com\/pat-hirschmann-maestro-installation-manual-guide\/\" title=\"Hirschmann Maestro Installation\" target=\"_blank\"\u003e\u003cspan style=\"line-height: 1.4; font-size: 15px;\"\u003eClick Here for Sample Installation \u003c\/span\u003e\u003c\/a\u003e\u003c\/p\u003e\n\u003cul\u003e\u003c\/ul\u003e\n\u003cul\u003e\u003c\/ul\u003e\n\u003cdiv class=\"flex flex-grow flex-col max-w-full\"\u003e\n\u003cdiv class=\"min-h-[20px] text-message flex flex-col items-start whitespace-pre-wrap break-words [.text-message+\u0026amp;]:mt-5 juice:w-full juice:items-end overflow-x-auto gap-2\" dir=\"auto\" data-message-id=\"28111606-77df-498e-a100-914bb42af4fc\" data-message-author-role=\"assistant\"\u003e\n\u003cdiv class=\"flex w-full flex-col gap-1 juice:empty:hidden juice:first:pt-[3px]\"\u003e\n\u003cdiv class=\"markdown prose w-full break-words dark:prose-invert light\"\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003ch3\u003eKey Features\u003c\/h3\u003e\n\u003cp\u003e\u003cstrong\u003e1. Precise Load Monitoring:\u003c\/strong\u003e The QScale Maestro provides accurate, real-time information about load weights and their positions relative to the crane's capacity. This feature helps prevent overloading, reducing the risk of accidents and equipment damage.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e2. User-Friendly Interface:\u003c\/strong\u003e The system boasts a clear, easy-to-read display with a touch-screen interface, making it accessible for operators of all experience levels. This intuitive design minimizes operator error and enhances productivity.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e3. Customizable Settings:\u003c\/strong\u003e Operators can tailor alarms and warnings based on specific load limits, boom angles, and other critical parameters. This flexibility ensures the system can adapt to various crane types and operational scenarios.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e4. Integrated Data Logging:\u003c\/strong\u003e The QScale Maestro records key operational data such as load weights and system alerts. This information can be reviewed to improve operational practices, ensure safety compliance, and identify areas for improvement.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e5. Robust Construction:\u003c\/strong\u003e Designed for heavy-duty use, the QScale Maestro is durable and resistant to extreme environmental conditions, including temperature fluctuations, moisture, and dust.\u003c\/p\u003e\n\u003ch3\u003eBenefits\u003c\/h3\u003e\n\u003cp\u003e\u003cstrong\u003eEnhanced Safety:\u003c\/strong\u003e By providing precise load information and customizable warnings, the QScale Maestro helps maintain safe working practices.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eImproved Efficiency:\u003c\/strong\u003e The user-friendly interface and real-time data access allow operators to work more efficiently and make informed decisions quickly.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eReliability:\u003c\/strong\u003e The robust construction and integrated diagnostics ensure long-term reliability, reducing downtime and maintenance costs.\u003c\/p\u003e\n\u003cp\u003eIn summary, the WIKA QScale Maestro is a cutting-edge LMI system that significantly enhances crane safety and efficiency, making it an essential asset for modern crane operations.\u003c\/p\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp style=\"text-align: center;\"\u003e\u003cimg src=\"\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/BTS_Social_Proof_Narrow_398e8837-6873-4848-8a8e-26b11b44b295.png?v=1519189255\" alt=\"\"\u003e\u003c\/p\u003e\n\u003cp\u003e \u003c\/p\u003e"}

PAT HIRSCHMANN

Hirschmann Maestro PAT DS350 & DS50 Upgrade Kit

$ 9,898.00

{"id":8160974012583,"title":"WIKA qScale Maestro Load Indicator System","handle":"wika-qscale-maestro-load-indicator-system","description":"\u003cdiv class=\"flex flex-grow flex-col max-w-full\"\u003e\n\u003cdiv data-message-author-role=\"assistant\" data-message-id=\"28111606-77df-498e-a100-914bb42af4fc\" dir=\"auto\" class=\"min-h-[20px] text-message flex flex-col items-start whitespace-pre-wrap break-words [.text-message+\u0026amp;]:mt-5 juice:w-full juice:items-end overflow-x-auto gap-2\"\u003e\n\u003cdiv class=\"flex w-full flex-col gap-1 juice:empty:hidden juice:first:pt-[3px]\"\u003e\n\u003cdiv class=\"markdown prose w-full break-words dark:prose-invert light\"\u003e\n\u003cp\u003eThe qSCALE maestro is an upgrade solution for the DS150G, DS350G\/GW and existing\u003cbr\u003emaestro systems that are currently in the field. This system provides crane owners with a combination of the latest technology while incorporating many of the existing proven sensors and components.\u003c\/p\u003e\n\u003cul\u003e\n\u003cli\u003eUpgrade of existing DS150G, DS350G\/GW \u0026amp; maestro systems\u003c\/li\u003e\n\u003cli\u003eConverts existing software\/No re-calibration required\u003c\/li\u003e\n\u003cli\u003e Displays actual and allowable load, boom length, boom angle \u0026amp; load radius\u003c\/li\u003e\n\u003cli\u003e Integrated light-bar and event recorde\u003c\/li\u003e\n\u003cli\u003e Optional external light-tower featur\u003c\/li\u003e\n\u003cli\u003e vSCALE D2 console with 4.3“ color displa\u003c\/li\u003e\n\u003cli\u003e Operating temperature: -40°C to +70°\u003c\/li\u003e\n\u003cli\u003e Protection class: IP66\/67\u003c\/li\u003e\n\u003c\/ul\u003e\n\u003cp\u003eThe WIKA QScale Maestro is an advanced load moment indicator (LMI) system designed to enhance crane safety and operational efficiency. Known for its innovative technology and user-friendly interface, the QScale Maestro offers a range of features and benefits that make it an invaluable tool for crane operators.\u003c\/p\u003e\n\u003ch3\u003eKey Features\u003c\/h3\u003e\n\u003cp\u003e\u003cstrong\u003e1. Precise Load Monitoring:\u003c\/strong\u003e The QScale Maestro provides accurate, real-time information about load weights and their positions relative to the crane's capacity. This feature helps prevent overloading, reducing the risk of accidents and equipment damage.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e2. User-Friendly Interface:\u003c\/strong\u003e The system boasts a clear, easy-to-read display with a touch-screen interface, making it accessible for operators of all experience levels. This intuitive design minimizes operator error and enhances productivity.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e3. Customizable Settings:\u003c\/strong\u003e Operators can tailor alarms and warnings based on specific load limits, boom angles, and other critical parameters. This flexibility ensures the system can adapt to various crane types and operational scenarios.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e4. Integrated Data Logging:\u003c\/strong\u003e The QScale Maestro records key operational data such as load weights and system alerts. This information can be reviewed to improve operational practices, ensure safety compliance, and identify areas for improvement.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e5. Robust Construction:\u003c\/strong\u003e Designed for heavy-duty use, the QScale Maestro is durable and resistant to extreme environmental conditions, including temperature fluctuations, moisture, and dust.\u003c\/p\u003e\n\u003ch3\u003eBenefits\u003c\/h3\u003e\n\u003cp\u003e\u003cstrong\u003eEnhanced Safety:\u003c\/strong\u003e By providing precise load information and customizable warnings, the QScale Maestro helps maintain safe working practices.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eImproved Efficiency:\u003c\/strong\u003e The user-friendly interface and real-time data access allow operators to work more efficiently and make informed decisions quickly.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eReliability:\u003c\/strong\u003e The robust construction and integrated diagnostics ensure long-term reliability, reducing downtime and maintenance costs.\u003c\/p\u003e\n\u003cp\u003eIn summary, the WIKA QScale Maestro is a cutting-edge LMI system that significantly enhances crane safety and efficiency, making it an essential asset for modern crane operations.\u003c\/p\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003c!----\u003e","published_at":"2024-05-16T14:04:48-04:00","created_at":"2024-05-16T14:04:48-04:00","vendor":"PAT HIRSCHMANN","type":"CONSOLE DISPLAY","tags":["complete LMI replacement","Display","Hirschmann","PAT","WIKA"],"price":988900,"price_min":988900,"price_max":988900,"available":true,"price_varies":false,"compare_at_price":null,"compare_at_price_min":0,"compare_at_price_max":0,"compare_at_price_varies":false,"variants":[{"id":45439420760231,"title":"Default Title","option1":"Default Title","option2":null,"option3":null,"sku":"Maestro","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"WIKA qScale Maestro Load Indicator System","public_title":null,"options":["Default Title"],"price":988900,"weight":29484,"compare_at_price":null,"inventory_quantity":1,"inventory_management":"shopify","inventory_policy":"deny","barcode":"","requires_selling_plan":false,"selling_plan_allocations":[]}],"images":["\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PATHirschmannDS350Replacement.png?v=1715882235"],"featured_image":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PATHirschmannDS350Replacement.png?v=1715882235","options":["Title"],"media":[{"alt":null,"id":29209017745575,"position":1,"preview_image":{"aspect_ratio":1.502,"height":233,"width":350,"src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PATHirschmannDS350Replacement.png?v=1715882235"},"aspect_ratio":1.502,"height":233,"media_type":"image","src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/PATHirschmannDS350Replacement.png?v=1715882235","width":350}],"requires_selling_plan":false,"selling_plan_groups":[],"content":"\u003cdiv class=\"flex flex-grow flex-col max-w-full\"\u003e\n\u003cdiv data-message-author-role=\"assistant\" data-message-id=\"28111606-77df-498e-a100-914bb42af4fc\" dir=\"auto\" class=\"min-h-[20px] text-message flex flex-col items-start whitespace-pre-wrap break-words [.text-message+\u0026amp;]:mt-5 juice:w-full juice:items-end overflow-x-auto gap-2\"\u003e\n\u003cdiv class=\"flex w-full flex-col gap-1 juice:empty:hidden juice:first:pt-[3px]\"\u003e\n\u003cdiv class=\"markdown prose w-full break-words dark:prose-invert light\"\u003e\n\u003cp\u003eThe qSCALE maestro is an upgrade solution for the DS150G, DS350G\/GW and existing\u003cbr\u003emaestro systems that are currently in the field. This system provides crane owners with a combination of the latest technology while incorporating many of the existing proven sensors and components.\u003c\/p\u003e\n\u003cul\u003e\n\u003cli\u003eUpgrade of existing DS150G, DS350G\/GW \u0026amp; maestro systems\u003c\/li\u003e\n\u003cli\u003eConverts existing software\/No re-calibration required\u003c\/li\u003e\n\u003cli\u003e Displays actual and allowable load, boom length, boom angle \u0026amp; load radius\u003c\/li\u003e\n\u003cli\u003e Integrated light-bar and event recorde\u003c\/li\u003e\n\u003cli\u003e Optional external light-tower featur\u003c\/li\u003e\n\u003cli\u003e vSCALE D2 console with 4.3“ color displa\u003c\/li\u003e\n\u003cli\u003e Operating temperature: -40°C to +70°\u003c\/li\u003e\n\u003cli\u003e Protection class: IP66\/67\u003c\/li\u003e\n\u003c\/ul\u003e\n\u003cp\u003eThe WIKA QScale Maestro is an advanced load moment indicator (LMI) system designed to enhance crane safety and operational efficiency. Known for its innovative technology and user-friendly interface, the QScale Maestro offers a range of features and benefits that make it an invaluable tool for crane operators.\u003c\/p\u003e\n\u003ch3\u003eKey Features\u003c\/h3\u003e\n\u003cp\u003e\u003cstrong\u003e1. Precise Load Monitoring:\u003c\/strong\u003e The QScale Maestro provides accurate, real-time information about load weights and their positions relative to the crane's capacity. This feature helps prevent overloading, reducing the risk of accidents and equipment damage.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e2. User-Friendly Interface:\u003c\/strong\u003e The system boasts a clear, easy-to-read display with a touch-screen interface, making it accessible for operators of all experience levels. This intuitive design minimizes operator error and enhances productivity.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e3. Customizable Settings:\u003c\/strong\u003e Operators can tailor alarms and warnings based on specific load limits, boom angles, and other critical parameters. This flexibility ensures the system can adapt to various crane types and operational scenarios.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e4. Integrated Data Logging:\u003c\/strong\u003e The QScale Maestro records key operational data such as load weights and system alerts. This information can be reviewed to improve operational practices, ensure safety compliance, and identify areas for improvement.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003e5. Robust Construction:\u003c\/strong\u003e Designed for heavy-duty use, the QScale Maestro is durable and resistant to extreme environmental conditions, including temperature fluctuations, moisture, and dust.\u003c\/p\u003e\n\u003ch3\u003eBenefits\u003c\/h3\u003e\n\u003cp\u003e\u003cstrong\u003eEnhanced Safety:\u003c\/strong\u003e By providing precise load information and customizable warnings, the QScale Maestro helps maintain safe working practices.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eImproved Efficiency:\u003c\/strong\u003e The user-friendly interface and real-time data access allow operators to work more efficiently and make informed decisions quickly.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eReliability:\u003c\/strong\u003e The robust construction and integrated diagnostics ensure long-term reliability, reducing downtime and maintenance costs.\u003c\/p\u003e\n\u003cp\u003eIn summary, the WIKA QScale Maestro is a cutting-edge LMI system that significantly enhances crane safety and efficiency, making it an essential asset for modern crane operations.\u003c\/p\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003c\/div\u003e\n\u003c!----\u003e"}

PAT HIRSCHMANN

WIKA qScale Maestro Load Indicator System

$ 9,889.00

{"id":387622344,"title":"068-508-060-001 PAT Hirschmann LWG508 Cable Reel","handle":"068-508-060-001-pat-hirschmann-lwg-508-cable-reel","description":"\u003cp\u003e\u003cstrong\u003e68 508 06 0001\u003c\/strong\u003e or \u003cstrong\u003e068-508-060-001\u003c\/strong\u003e PAT Hirschmann LWG508\/01 cable reel with length and angle transmission. \u003cbr\u003e\u003c\/p\u003e\n\u003cp\u003ePAT Hirschmann LWG 508: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip. \u003c\/p\u003e\n\u003ch1\u003e PAT Hirschmann LWG508 ID Tag\u003cbr\u003e\n\u003c\/h1\u003e\n\u003cp\u003e\u003cimg alt=\"PAT Hirschmann LWG508 Cable Reel\" src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/PATHirschmannLWG508CableReelTag.jpg?v=1699987369\" width=\"535\" height=\"352\" style=\"display: block; margin-left: auto; margin-right: auto;\"\u003e\u003c\/p\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp\u003eA reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.\u003c\/p\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003ch2\u003eHirschmann LWG 508 Cable Reel Schematic\u003c\/h2\u003e\n\u003cp\u003e\u003cimg src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/Cable_Reel_LWG508_01_NEW.png?v=1740169838\" alt=\"\"\u003e\u003c\/p\u003e\n\u003ch3\u003ePAT Hirschmann LWG508 Information\u003cbr\u003e\n\u003c\/h3\u003e\n\u003cp\u003eThe Length-Angle Transducer: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip. \u003c\/p\u003e\n\u003cp\u003eA reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.\u003c\/p\u003e\n\u003cul\u003e\n\u003cli\u003eThe power supply voltage for both is -5.00V\u003c\/li\u003e\n\u003cli\u003eThe output signal for the length transducer is: -0.500V up to -4.500V\u003c\/li\u003e\n\u003cli\u003eThe output signal for the angle transducer is: -1.875V up to -3.125V\u003c\/li\u003e\n\u003c\/ul\u003e\n\u003cp\u003eLWG 508 Length Adjustment: Ensure that the length cable tension is correct with fully retracted boom by turning the cable reel 5 to 8 turns counterclockwise. Then remove cover form LWG and adjust counterclockwise the potentiometer to end stop.\u003c\/p\u003e\n\u003ch2\u003ePAT Hirschmann LWG 508 Length Cable Replacement\u003cbr\u003e\n\u003c\/h2\u003e\n\u003col\u003e\n\u003cli\u003eCut old cable at cable drum\u003c\/li\u003e\n\u003cli\u003eDisconnect damaged length cable from junction box at the boom nose.\u003c\/li\u003e\n\u003cli\u003eOpen cable reel cover and disconnect wiring from connection block. Pull 7 conductor cable out of strain relief.\u003c\/li\u003e\n\u003cli\u003eRemove cable reel from mounting brackets.\u003c\/li\u003e\n\u003cli\u003eRemove damaged length cable, which is mounted to the slip rings in the cable reel, from slipring connection. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eOn the back side of the cable reel, open the strain relief attached to the axle in the center of the drum. Pull existing length cable out of the cable reel.\u003c\/li\u003e\n\u003cli\u003ePull new length cable through the hole, pipe and strain relief and push it through the axle of the reeling drum. Tighten strain relief to ensure sealing.\u003c\/li\u003e\n\u003cli\u003eReconnect the length cable to the slipring. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eRemount cable reel to the boom.\u003c\/li\u003e\n\u003cli\u003eTurn reeling drum clockwise to spool the new cable neatly onto the drum.\u003c\/li\u003e\n\u003cli\u003eSet preload on cable reel by turning the drum counter-clockwise 5 to 8 turns.\u003c\/li\u003e\n\u003cli\u003eWrap the new length cable around the boom tip anchor pin (4 or 5 wraps) and secure with tie wraps. Leave enough length cable to connect into the boom tip junction box.\u003c\/li\u003e\n\u003cli\u003eConnect the length cable into the boom tip junction box.\u003c\/li\u003e\n\u003cli\u003eReset length potentiometer in length angle transducer (screw is located in center of white gear); with boom fully retracted, turn potentiometer carefully counter-clockwise until it stops. Recheck length and angle display. \u003cbr\u003e\n\u003c\/li\u003e\n\u003c\/ol\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp\u003e \u003c\/p\u003e","published_at":"2018-06-15T07:06:28-04:00","created_at":"2014-11-27T12:35:12-05:00","vendor":"PAT HIRSCHMANN","type":"CABLE REEL","tags":["Cable Reel","Hirschmann","LWG508","PAT"],"price":549800,"price_min":549800,"price_max":549800,"available":false,"price_varies":false,"compare_at_price":599900,"compare_at_price_min":599900,"compare_at_price_max":599900,"compare_at_price_varies":false,"variants":[{"id":1034619048,"title":"Default Title","option1":"Default Title","option2":null,"option3":null,"sku":"068-508-060-001","requires_shipping":true,"taxable":true,"featured_image":null,"available":false,"name":"068-508-060-001 PAT Hirschmann LWG508 Cable Reel","public_title":null,"options":["Default Title"],"price":549800,"weight":41277,"compare_at_price":599900,"inventory_quantity":0,"inventory_management":"shopify","inventory_policy":"deny","barcode":"","requires_selling_plan":false,"selling_plan_allocations":[]}],"images":["\/\/store.bodetechnicalservices.com\/cdn\/shop\/products\/PAT-Hirschmann-Cable-Reel_605eec12-31c3-430b-9a3e-0420c22cc30b.jpg?v=1519747870","\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/Cable_Reel_LWG508_01_NEW.png?v=1740169838"],"featured_image":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/products\/PAT-Hirschmann-Cable-Reel_605eec12-31c3-430b-9a3e-0420c22cc30b.jpg?v=1519747870","options":["Title"],"media":[{"alt":null,"id":14185398368,"position":1,"preview_image":{"aspect_ratio":1.368,"height":467,"width":639,"src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/products\/PAT-Hirschmann-Cable-Reel_605eec12-31c3-430b-9a3e-0420c22cc30b.jpg?v=1519747870"},"aspect_ratio":1.368,"height":467,"media_type":"image","src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/products\/PAT-Hirschmann-Cable-Reel_605eec12-31c3-430b-9a3e-0420c22cc30b.jpg?v=1519747870","width":639},{"alt":null,"id":30794914988199,"position":2,"preview_image":{"aspect_ratio":1.404,"height":1768,"width":2482,"src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/Cable_Reel_LWG508_01_NEW.png?v=1740169838"},"aspect_ratio":1.404,"height":1768,"media_type":"image","src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/Cable_Reel_LWG508_01_NEW.png?v=1740169838","width":2482}],"requires_selling_plan":false,"selling_plan_groups":[],"content":"\u003cp\u003e\u003cstrong\u003e68 508 06 0001\u003c\/strong\u003e or \u003cstrong\u003e068-508-060-001\u003c\/strong\u003e PAT Hirschmann LWG508\/01 cable reel with length and angle transmission. \u003cbr\u003e\u003c\/p\u003e\n\u003cp\u003ePAT Hirschmann LWG 508: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip. \u003c\/p\u003e\n\u003ch1\u003e PAT Hirschmann LWG508 ID Tag\u003cbr\u003e\n\u003c\/h1\u003e\n\u003cp\u003e\u003cimg alt=\"PAT Hirschmann LWG508 Cable Reel\" src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/PATHirschmannLWG508CableReelTag.jpg?v=1699987369\" width=\"535\" height=\"352\" style=\"display: block; margin-left: auto; margin-right: auto;\"\u003e\u003c\/p\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp\u003eA reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.\u003c\/p\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003ch2\u003eHirschmann LWG 508 Cable Reel Schematic\u003c\/h2\u003e\n\u003cp\u003e\u003cimg src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/Cable_Reel_LWG508_01_NEW.png?v=1740169838\" alt=\"\"\u003e\u003c\/p\u003e\n\u003ch3\u003ePAT Hirschmann LWG508 Information\u003cbr\u003e\n\u003c\/h3\u003e\n\u003cp\u003eThe Length-Angle Transducer: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip. \u003c\/p\u003e\n\u003cp\u003eA reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.\u003c\/p\u003e\n\u003cul\u003e\n\u003cli\u003eThe power supply voltage for both is -5.00V\u003c\/li\u003e\n\u003cli\u003eThe output signal for the length transducer is: -0.500V up to -4.500V\u003c\/li\u003e\n\u003cli\u003eThe output signal for the angle transducer is: -1.875V up to -3.125V\u003c\/li\u003e\n\u003c\/ul\u003e\n\u003cp\u003eLWG 508 Length Adjustment: Ensure that the length cable tension is correct with fully retracted boom by turning the cable reel 5 to 8 turns counterclockwise. Then remove cover form LWG and adjust counterclockwise the potentiometer to end stop.\u003c\/p\u003e\n\u003ch2\u003ePAT Hirschmann LWG 508 Length Cable Replacement\u003cbr\u003e\n\u003c\/h2\u003e\n\u003col\u003e\n\u003cli\u003eCut old cable at cable drum\u003c\/li\u003e\n\u003cli\u003eDisconnect damaged length cable from junction box at the boom nose.\u003c\/li\u003e\n\u003cli\u003eOpen cable reel cover and disconnect wiring from connection block. Pull 7 conductor cable out of strain relief.\u003c\/li\u003e\n\u003cli\u003eRemove cable reel from mounting brackets.\u003c\/li\u003e\n\u003cli\u003eRemove damaged length cable, which is mounted to the slip rings in the cable reel, from slipring connection. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eOn the back side of the cable reel, open the strain relief attached to the axle in the center of the drum. Pull existing length cable out of the cable reel.\u003c\/li\u003e\n\u003cli\u003ePull new length cable through the hole, pipe and strain relief and push it through the axle of the reeling drum. Tighten strain relief to ensure sealing.\u003c\/li\u003e\n\u003cli\u003eReconnect the length cable to the slipring. \u003cbr\u003e\n\u003c\/li\u003e\n\u003cli\u003eRemount cable reel to the boom.\u003c\/li\u003e\n\u003cli\u003eTurn reeling drum clockwise to spool the new cable neatly onto the drum.\u003c\/li\u003e\n\u003cli\u003eSet preload on cable reel by turning the drum counter-clockwise 5 to 8 turns.\u003c\/li\u003e\n\u003cli\u003eWrap the new length cable around the boom tip anchor pin (4 or 5 wraps) and secure with tie wraps. Leave enough length cable to connect into the boom tip junction box.\u003c\/li\u003e\n\u003cli\u003eConnect the length cable into the boom tip junction box.\u003c\/li\u003e\n\u003cli\u003eReset length potentiometer in length angle transducer (screw is located in center of white gear); with boom fully retracted, turn potentiometer carefully counter-clockwise until it stops. Recheck length and angle display. \u003cbr\u003e\n\u003c\/li\u003e\n\u003c\/ol\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp\u003e \u003c\/p\u003e"}

PAT HIRSCHMANN

068-508-060-001 PAT Hirschmann LWG508 Cable Reel

CALL TO PRE-ORDER NOW

{"id":8385381367975,"title":"031-300-060-648 National Crane Hirschmann Mentor Computer LMI Replacement","handle":"031-300-060-648-national-crane-hirschmann-mentor-computer-lmi-replacement","description":"\u003ch1\u003e031-300-060-648 Hirschmann Mentor Console for National Boom Truck Crane\u003c\/h1\u003e\n\u003cp\u003e\u003cspan style=\"text-decoration: underline;\"\u003e\u003cem\u003ePLEASE NOTE: The Mentor Console LMI does need to be programmed for your specific crane model and serial number. Please contact us directly to confirm your crane calibration software is on file. \u003c\/em\u003e\u003c\/span\u003e\u003c\/p\u003e\n\u003cp\u003eThe 031-300-060-648 National Crane Hirschmann Mentor console is a critical component of the Hirschmann Load Moment Indicator (LMI) system, designed to aid crane operators by providing real-time, essential operational data. The console integrates advanced monitoring and control features that enhance crane safety and performance, offering significant benefits to operators and construction companies alike.\u003c\/p\u003e\n\u003cdiv style=\"text-align: center;\"\u003e\u003ca rel=\"noopener\" title=\"Hirschmann iVisor Mentor LMI Console Manual\" href=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/Hirschmann_Mentor_Operators_Manual.pdf?v=1729615142\" target=\"_blank\"\u003e\u003cimg style=\"margin-bottom: 16px; float: none;\" alt=\"Hirschmann Mentor iVisor Console LMI Crane Computer\" src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/BTS_Crane_Parts_Hirschmann_Mentor_LMI_Console.png?v=1729615416\" width=\"362\" height=\"471\"\u003e\u003c\/a\u003e\u003c\/div\u003e\n\u003ch4 style=\"text-align: center;\"\u003e\u003cspan style=\"color: rgb(43, 0, 255);\"\u003e\u003ca href=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/Hirschmann_Mentor_Operators_Manual.pdf?v=1729615142\" title=\"Hirschmann Mentor Console LMI for National Crane Replacement\" style=\"color: rgb(43, 0, 255);\" rel=\"noopener\" target=\"_blank\"\u003e\u003cstrong\u003ePDF Copy of iVisor Mentor Manual HERE\u003c\/strong\u003e\u003c\/a\u003e\u003c\/span\u003e\u003c\/h4\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003ch2\u003eKey Features of the Hirschmann Mentor Console\u003c\/h2\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eUser-Friendly Interface\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe iVisor Hirschmann Mentor console is designed with a large, easy-to-read Liquid Crystal Display (LCD), which provides real-time information to the crane operator. The LCD has a wide temperature range and transflective properties, ensuring visibility in both bright sunlight and low-light conditions. The display automatically adjusts contrast according to surrounding temperatures, allowing operators to work efficiently regardless of environmental conditions. Furthermore, the console is backlit continuously during operation, enhancing visibility during nighttime operations.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eCrane Configuration Setup\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eOne of the most important features of the Mentor console is its ability to assist the operator in setting up the crane’s operating configuration. It allows the operator to select the crane's mode, outrigger configuration, hoist, and reeving. The system stores previously used configurations and automatically loads them when needed, saving the operator time and reducing the chance for human error during setup. This interactive process ensures the crane is properly configured before operation begins, reducing the risk of accidents.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eOverload and Anti-Two-Block Protection\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe Mentor console includes crucial safety features such as load moment limit and prewarning lights. When a crane approaches its rated load capacity, a yellow prewarning light activates, alerting the operator to the approaching limit. Should the crane reach the rated load, a red limit light, along with an audible alarm, is triggered. The system can also disable specific crane functions—such as hoisting up, telescoping out, or booming down—to prevent overloading. Additionally, the Anti-Two-Block (A2B) system warns the operator of a potential over-hoist condition, further safeguarding both the equipment and personnel.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003ePrecise Load Monitoring and Reeving Selection\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe console displays critical parameters such as load moment, actual load, capacity, boom length, boom angle, tip height, and reeving configuration (parts-of-line). It allows operators to input the reeving configuration manually and ensures accurate load readings by adjusting the displayed net load. The ability to monitor these parameters in real-time provides operators with the necessary information to make quick decisions while maintaining safety margins.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eLimit Settings and Virtual Walls\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eAnother unique feature of the National Crane Mentor console is its ability to set geometric limits for boom angle, radius, and tip height. Operators can define maximum and minimum limits for these parameters, with the system alerting the operator if any of the limits are exceeded. Additionally, the \"Virtual Wall\" feature allows operators to set a defined working area for the crane, effectively creating a boundary to avoid obstacles like buildings or power lines. The system alerts the operator with visual and audible alarms if the crane approaches or crosses these virtual walls, improving situational awareness.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eAlarm Management and Bypass Functionality\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe console includes an alarm stop button that allows operators to silence alarms for short durations when necessary. The system is equipped with bypass keys that can override certain functions if required, such as load moment and anti-two-block warnings. These overrides are intended for emergency use and should be applied with caution to prevent dangerous situations.\u003c\/p\u003e\n\u003cdiv style=\"text-align: center;\"\u003e\u003cimg style=\"float: none;\" alt=\"Hirschmann Mentor LMI Console Computer for Cranes Schematic\" src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/Hirschmann_Mentor_LMI_Computer_Component_Drawing.png?v=1729615548\"\u003e\u003c\/div\u003e\n\u003ch3\u003e\u003cbr\u003e\u003c\/h3\u003e\n\u003ch3\u003e\u003cbr\u003e\u003c\/h3\u003e\n\u003ch3\u003eBenefits of the National Crane Hirschmann iVisor Mentor Console\u003c\/h3\u003e\n\u003cp\u003e\u003cstrong\u003eEnhanced Safety\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe Mentor console significantly enhances crane operation safety by providing real-time feedback on critical operating conditions. Its overload protection, anti-two-block warning, and geometric limit settings all help reduce the risk of accidents caused by equipment overload or operator error.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eOperational Efficiency\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe console’s ability to store previous configurations streamlines the setup process for operators, allowing cranes to be deployed faster and with greater accuracy. This reduces downtime and enhances operational efficiency on the job site.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eOperator Confidence\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe Mentor console’s clear and comprehensive display of crane parameters allows operators to work with greater confidence, knowing they have full control and awareness of the crane’s operating conditions. The safety alarms and limit-setting features further instill trust in the system’s ability to prevent dangerous situations.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eImproved Equipment Longevity\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eBy preventing overloads and dangerous operating conditions, the Mentor console helps reduce wear and tear on the crane, thereby prolonging its service life and minimizing the need for costly repairs.\u003c\/p\u003e\n\u003cp\u003eThe iVisor Hirschmann Mentor console is a powerful tool for National crane operators, offering advanced monitoring and control features that enhance both safety and efficiency. Its real-time data display, easy configuration setup, and safety features like overload protection and virtual wall limits make it an indispensable component of modern crane operation.\u003c\/p\u003e","published_at":"2024-10-22T12:31:04-04:00","created_at":"2024-10-22T12:31:04-04:00","vendor":"PAT HIRSCHMANN","type":"CONSOLE DISPLAY","tags":["Display","Hirschmann","LMI","National Crane","PAT"],"price":589800,"price_min":589800,"price_max":589800,"available":true,"price_varies":false,"compare_at_price":null,"compare_at_price_min":0,"compare_at_price_max":0,"compare_at_price_varies":false,"variants":[{"id":46209319829671,"title":"Default Title","option1":"Default Title","option2":null,"option3":null,"sku":"031-300-060-648","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"031-300-060-648 National Crane Hirschmann Mentor Computer LMI Replacement","public_title":null,"options":["Default Title"],"price":589800,"weight":24948,"compare_at_price":null,"inventory_quantity":0,"inventory_management":"shopify","inventory_policy":"continue","barcode":"","requires_selling_plan":false,"selling_plan_allocations":[]}],"images":["\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/031-300-060-648NationalMentorConsoleReplacement.gif?v=1729613791"],"featured_image":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/031-300-060-648NationalMentorConsoleReplacement.gif?v=1729613791","options":["Title"],"media":[{"alt":null,"id":30086576472231,"position":1,"preview_image":{"aspect_ratio":1.489,"height":235,"width":350,"src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/031-300-060-648NationalMentorConsoleReplacement.gif?v=1729613791"},"aspect_ratio":1.489,"height":235,"media_type":"image","src":"\/\/store.bodetechnicalservices.com\/cdn\/shop\/files\/031-300-060-648NationalMentorConsoleReplacement.gif?v=1729613791","width":350}],"requires_selling_plan":false,"selling_plan_groups":[],"content":"\u003ch1\u003e031-300-060-648 Hirschmann Mentor Console for National Boom Truck Crane\u003c\/h1\u003e\n\u003cp\u003e\u003cspan style=\"text-decoration: underline;\"\u003e\u003cem\u003ePLEASE NOTE: The Mentor Console LMI does need to be programmed for your specific crane model and serial number. Please contact us directly to confirm your crane calibration software is on file. \u003c\/em\u003e\u003c\/span\u003e\u003c\/p\u003e\n\u003cp\u003eThe 031-300-060-648 National Crane Hirschmann Mentor console is a critical component of the Hirschmann Load Moment Indicator (LMI) system, designed to aid crane operators by providing real-time, essential operational data. The console integrates advanced monitoring and control features that enhance crane safety and performance, offering significant benefits to operators and construction companies alike.\u003c\/p\u003e\n\u003cdiv style=\"text-align: center;\"\u003e\u003ca rel=\"noopener\" title=\"Hirschmann iVisor Mentor LMI Console Manual\" href=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/Hirschmann_Mentor_Operators_Manual.pdf?v=1729615142\" target=\"_blank\"\u003e\u003cimg style=\"margin-bottom: 16px; float: none;\" alt=\"Hirschmann Mentor iVisor Console LMI Crane Computer\" src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/BTS_Crane_Parts_Hirschmann_Mentor_LMI_Console.png?v=1729615416\" width=\"362\" height=\"471\"\u003e\u003c\/a\u003e\u003c\/div\u003e\n\u003ch4 style=\"text-align: center;\"\u003e\u003cspan style=\"color: rgb(43, 0, 255);\"\u003e\u003ca href=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/Hirschmann_Mentor_Operators_Manual.pdf?v=1729615142\" title=\"Hirschmann Mentor Console LMI for National Crane Replacement\" style=\"color: rgb(43, 0, 255);\" rel=\"noopener\" target=\"_blank\"\u003e\u003cstrong\u003ePDF Copy of iVisor Mentor Manual HERE\u003c\/strong\u003e\u003c\/a\u003e\u003c\/span\u003e\u003c\/h4\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003ch2\u003eKey Features of the Hirschmann Mentor Console\u003c\/h2\u003e\n\u003cp\u003e \u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eUser-Friendly Interface\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe iVisor Hirschmann Mentor console is designed with a large, easy-to-read Liquid Crystal Display (LCD), which provides real-time information to the crane operator. The LCD has a wide temperature range and transflective properties, ensuring visibility in both bright sunlight and low-light conditions. The display automatically adjusts contrast according to surrounding temperatures, allowing operators to work efficiently regardless of environmental conditions. Furthermore, the console is backlit continuously during operation, enhancing visibility during nighttime operations.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eCrane Configuration Setup\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eOne of the most important features of the Mentor console is its ability to assist the operator in setting up the crane’s operating configuration. It allows the operator to select the crane's mode, outrigger configuration, hoist, and reeving. The system stores previously used configurations and automatically loads them when needed, saving the operator time and reducing the chance for human error during setup. This interactive process ensures the crane is properly configured before operation begins, reducing the risk of accidents.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eOverload and Anti-Two-Block Protection\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe Mentor console includes crucial safety features such as load moment limit and prewarning lights. When a crane approaches its rated load capacity, a yellow prewarning light activates, alerting the operator to the approaching limit. Should the crane reach the rated load, a red limit light, along with an audible alarm, is triggered. The system can also disable specific crane functions—such as hoisting up, telescoping out, or booming down—to prevent overloading. Additionally, the Anti-Two-Block (A2B) system warns the operator of a potential over-hoist condition, further safeguarding both the equipment and personnel.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003ePrecise Load Monitoring and Reeving Selection\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe console displays critical parameters such as load moment, actual load, capacity, boom length, boom angle, tip height, and reeving configuration (parts-of-line). It allows operators to input the reeving configuration manually and ensures accurate load readings by adjusting the displayed net load. The ability to monitor these parameters in real-time provides operators with the necessary information to make quick decisions while maintaining safety margins.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eLimit Settings and Virtual Walls\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eAnother unique feature of the National Crane Mentor console is its ability to set geometric limits for boom angle, radius, and tip height. Operators can define maximum and minimum limits for these parameters, with the system alerting the operator if any of the limits are exceeded. Additionally, the \"Virtual Wall\" feature allows operators to set a defined working area for the crane, effectively creating a boundary to avoid obstacles like buildings or power lines. The system alerts the operator with visual and audible alarms if the crane approaches or crosses these virtual walls, improving situational awareness.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eAlarm Management and Bypass Functionality\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe console includes an alarm stop button that allows operators to silence alarms for short durations when necessary. The system is equipped with bypass keys that can override certain functions if required, such as load moment and anti-two-block warnings. These overrides are intended for emergency use and should be applied with caution to prevent dangerous situations.\u003c\/p\u003e\n\u003cdiv style=\"text-align: center;\"\u003e\u003cimg style=\"float: none;\" alt=\"Hirschmann Mentor LMI Console Computer for Cranes Schematic\" src=\"https:\/\/cdn.shopify.com\/s\/files\/1\/0702\/9949\/files\/Hirschmann_Mentor_LMI_Computer_Component_Drawing.png?v=1729615548\"\u003e\u003c\/div\u003e\n\u003ch3\u003e\u003cbr\u003e\u003c\/h3\u003e\n\u003ch3\u003e\u003cbr\u003e\u003c\/h3\u003e\n\u003ch3\u003eBenefits of the National Crane Hirschmann iVisor Mentor Console\u003c\/h3\u003e\n\u003cp\u003e\u003cstrong\u003eEnhanced Safety\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe Mentor console significantly enhances crane operation safety by providing real-time feedback on critical operating conditions. Its overload protection, anti-two-block warning, and geometric limit settings all help reduce the risk of accidents caused by equipment overload or operator error.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eOperational Efficiency\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe console’s ability to store previous configurations streamlines the setup process for operators, allowing cranes to be deployed faster and with greater accuracy. This reduces downtime and enhances operational efficiency on the job site.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eOperator Confidence\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eThe Mentor console’s clear and comprehensive display of crane parameters allows operators to work with greater confidence, knowing they have full control and awareness of the crane’s operating conditions. The safety alarms and limit-setting features further instill trust in the system’s ability to prevent dangerous situations.\u003c\/p\u003e\n\u003cp\u003e\u003cstrong\u003eImproved Equipment Longevity\u003c\/strong\u003e\u003c\/p\u003e\n\u003cp\u003eBy preventing overloads and dangerous operating conditions, the Mentor console helps reduce wear and tear on the crane, thereby prolonging its service life and minimizing the need for costly repairs.\u003c\/p\u003e\n\u003cp\u003eThe iVisor Hirschmann Mentor console is a powerful tool for National crane operators, offering advanced monitoring and control features that enhance both safety and efficiency. Its real-time data display, easy configuration setup, and safety features like overload protection and virtual wall limits make it an indispensable component of modern crane operation.\u003c\/p\u003e"}

$ 5,898.00