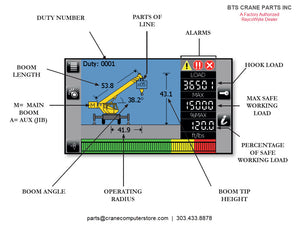

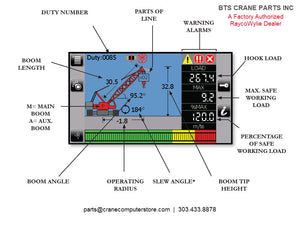

- Continuous display of Load, Hoist, Parts of line, Radius, boom length, boom angle and % of maximum capacity

- Operator adjustable low, high angle, length, height and radius limits

- Full lockout capabilities if installed on your crane

- Audible and visual alarms indicating two-block, load limit conditions

- Diagnostic menu and continuous error detection and recording

- Quick and easy installation

- USB file transfers

- Multi-language: English, Spanish, French

- Selectable units metric or US

Grove Crane Computer LMI Replacement

-

100% ORIGINAL AND QUALITY

-

24 MONTHS GUARANTEE

-

1-4 DAYS DELIVERY

Grove Crane Computer LMI Replacement Description

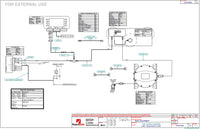

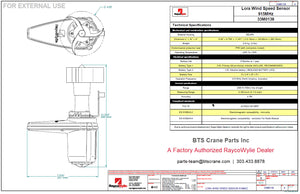

Many of the old PAT DS350 LMI consoles installed in Grove cranes are now obsolete. Repairs are frustrating and end up fixing one failing item after another. This Grove crane load moment indicator LMI computer replacement systeme is perfectly suited to pre 2004 year telescopic cranes requiring a simple load monitoring solution with a single cable reel length angle sensor. The RaycoWylie i4300 is the ideal replacement for aging PAT DS350 systems and will bring your machine up to date with a 4.3 inch full color display, state of the art reliable sensors, and rugged long lasting trouble-free construction. The i4300 crane system supports multiple sensors including boom angle / length cable reel sensor, two load sensors, boom tip anti two block, and winds speed. Available for single reel telescopic cranes (hoist or total moment sensing) all sensors and the display itself are a minimum of IP67 water resistance rating.

Starting at $8,795 for smaller cranes

GET A QUOTE

Grove Crane Computer LMI Replacement Features

GET A QUOTE

Grove Crane Computer LMI Replacement Components

Recent Crane LMI Replacement Projects

We have provided crane LMI computer replacement options and/or parts for hundreds of customers over the years. Here are a few of the most recent complete LMI computer replacement system jobs. Most of these jobs involve the replacement of an aging PAT DS350 Vertical LMI system that has become unreliable however the crane itself is in great shape and continues to be used. Some of our customers come to us without any LMI on their crane and we work with them to get a complete new system for them.

Link Belt HC248H

This customer is a large concrete construction provide in the mid Atlantic east coast region. They approached BTS about a replacement for their PAT DS350 Vertical RCI console. Unfortunately the lead time to get a replacement from Europe was about 4 months and cost around $15,000. The customer was not able to wait that long, nor did it make any sense to spend that amount of money to replace one component of such an aging system. In the end we were able to provide a complete new RCI system to them for less than the price it would have cost for the replacement display.

National Boom Truck Crane

We usually complete several of these boom truck systems a year for customers, many of whom are in the tree service industry. The National boom truck is particularly simple as it requires only a load sensor and a cable reel. The original anti two block system can be reused if it is in good condition, thereby saving that expense. Programming is simple and the customer gets a full color display with full load charts and lockout capabilities.

Grove TM1300

This customer was a large builder in the northwest focusing on large commercial facilities as well as custom build homes. Their crane was in overall good condition as it had been well maintained and had conservative use in their construction projects. The crane's old PAT DS350 LMI system however had deteriorated significantly and was giving constant E95 error codes (undetermined error). We worked with this customer to find an LMI replacement system that was in their budget but with functionality on both main and auxiliary line and was rugged enough to withstand the northern winters and provide years of trouble free use.

Grove RT528C

This customer operates an excavation and construction company in the midwest providing highway and bridge construction services as well as support to the oil and gas pipeline industry. This Grove crane was from the mid nineties however like many others, was in great shape and well cared for. The computer system however was an old PAT DS350 GW system that had outlived its useful life. This project was a simple swap out of the old system for the new. The customer got full load carts and will have years of trouble free use of this crane computer system.

Grove Crane Computer LMI Replacement Description

Many of the old PAT DS350 LMI consoles installed in Grove cranes are now obsolete. Repairs are frustrating and end up fixing one failing item after another. This Grove crane load moment indicator LMI computer replacement systeme is perfectly suited to pre 2004 year telescopic cranes requiring a simple load monitoring solution with a single cable reel length angle sensor. The RaycoWylie i4300 is the ideal replacement for aging PAT DS350 systems and will bring your machine up to date with a 4.3 inch full color display, state of the art reliable sensors, and rugged long lasting trouble-free construction. The i4300 crane system supports multiple sensors including boom angle / length cable reel sensor, two load sensors, boom tip anti two block, and winds speed. Available for single reel telescopic cranes (hoist or total moment sensing) all sensors and the display itself are a minimum of IP67 water resistance rating.

Starting at $8,795 for smaller cranes

GET A QUOTE

Grove Crane Computer LMI Replacement Features

- Continuous display of Load, Hoist, Parts of line, Radius, boom length, boom angle and % of maximum capacity

- Operator adjustable low, high angle, length, height and radius limits

- Full lockout capabilities if installed on your crane

- Audible and visual alarms indicating two-block, load limit conditions

- Diagnostic menu and continuous error detection and recording

- Quick and easy installation

- USB file transfers

- Multi-language: English, Spanish, French

- Selectable units metric or US

GET A QUOTE

Grove Crane Computer LMI Replacement Components

Recent Crane LMI Replacement Projects

We have provided crane LMI computer replacement options and/or parts for hundreds of customers over the years. Here are a few of the most recent complete LMI computer replacement system jobs. Most of these jobs involve the replacement of an aging PAT DS350 Vertical LMI system that has become unreliable however the crane itself is in great shape and continues to be used. Some of our customers come to us without any LMI on their crane and we work with them to get a complete new system for them.

Link Belt HC248H

This customer is a large concrete construction provide in the mid Atlantic east coast region. They approached BTS about a replacement for their PAT DS350 Vertical RCI console. Unfortunately the lead time to get a replacement from Europe was about 4 months and cost around $15,000. The customer was not able to wait that long, nor did it make any sense to spend that amount of money to replace one component of such an aging system. In the end we were able to provide a complete new RCI system to them for less than the price it would have cost for the replacement display.

National Boom Truck Crane

We usually complete several of these boom truck systems a year for customers, many of whom are in the tree service industry. The National boom truck is particularly simple as it requires only a load sensor and a cable reel. The original anti two block system can be reused if it is in good condition, thereby saving that expense. Programming is simple and the customer gets a full color display with full load charts and lockout capabilities.

Grove TM1300

This customer was a large builder in the northwest focusing on large commercial facilities as well as custom build homes. Their crane was in overall good condition as it had been well maintained and had conservative use in their construction projects. The crane's old PAT DS350 LMI system however had deteriorated significantly and was giving constant E95 error codes (undetermined error). We worked with this customer to find an LMI replacement system that was in their budget but with functionality on both main and auxiliary line and was rugged enough to withstand the northern winters and provide years of trouble free use.

Grove RT528C

This customer operates an excavation and construction company in the midwest providing highway and bridge construction services as well as support to the oil and gas pipeline industry. This Grove crane was from the mid nineties however like many others, was in great shape and well cared for. The computer system however was an old PAT DS350 GW system that had outlived its useful life. This project was a simple swap out of the old system for the new. The customer got full load carts and will have years of trouble free use of this crane computer system.

Have a Question?

The BTS Parts Team is always available to answer any questions you may have. Please feel free to leave a message and we will reply within 24 hours.

4737 North Ocean Drive

Suite 206

Fort Lauderdale FL 33308