- BTS Crane Parts StoreHome

- Featured Products

- Featured Products

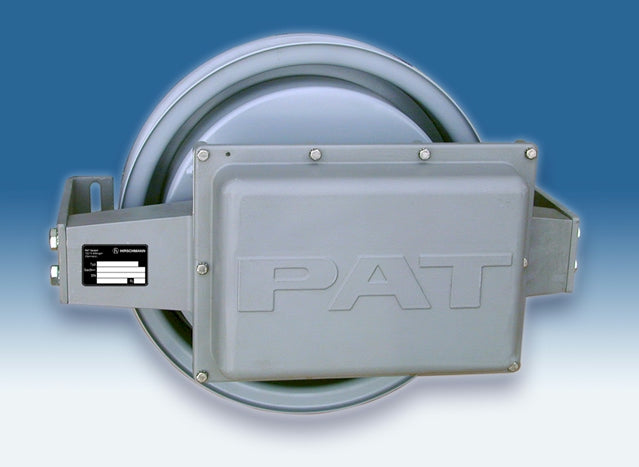

- 068-508-060-001 PAT Hirschmann LWG508 Cable Reel

- 068-508-060-001 PAT Hirschmann LWG508 Cable Reel

-

100% ORIGINAL AND QUALITY

-

24 MONTHS GUARANTEE

-

1-4 DAYS DELIVERY

68 508 06 0001 or 068-508-060-001 PAT Hirschmann LWG508/01 cable reel with length and angle transmission.

PAT Hirschmann LWG 508: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip.

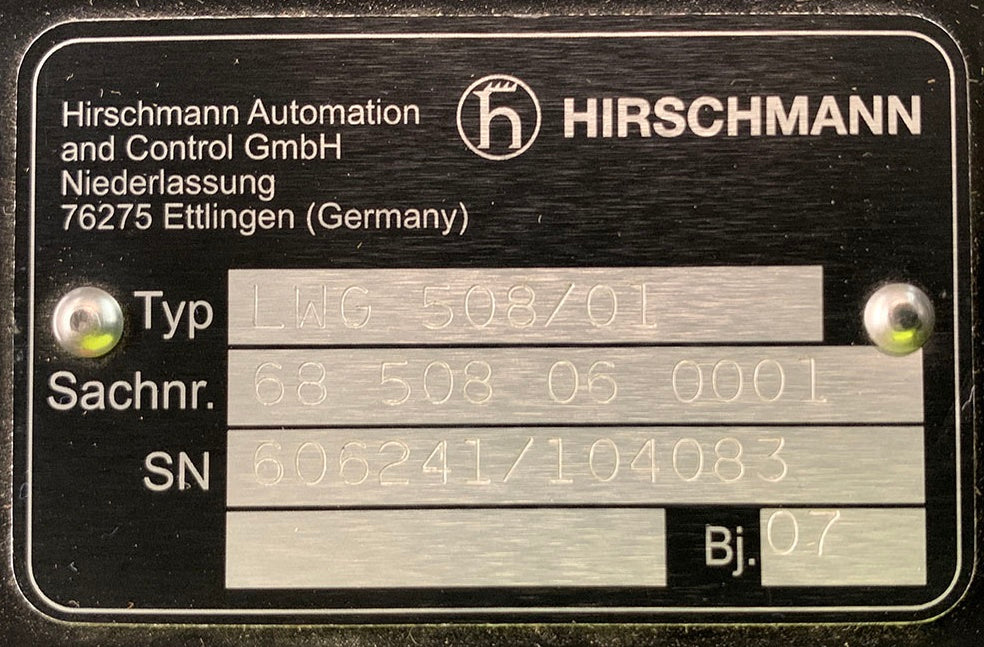

PAT Hirschmann LWG508 ID Tag

A reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.

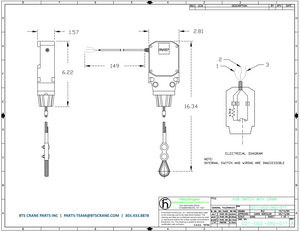

Hirschmann LWG 508 Cable Reel Schematic

PAT Hirschmann LWG508 Information

The Length-Angle Transducer: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip.

A reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.

- The power supply voltage for both is -5.00V

- The output signal for the length transducer is: -0.500V up to -4.500V

- The output signal for the angle transducer is: -1.875V up to -3.125V

LWG 508 Length Adjustment: Ensure that the length cable tension is correct with fully retracted boom by turning the cable reel 5 to 8 turns counterclockwise. Then remove cover form LWG and adjust counterclockwise the potentiometer to end stop.

PAT Hirschmann LWG 508 Length Cable Replacement

- Cut old cable at cable drum

- Disconnect damaged length cable from junction box at the boom nose.

- Open cable reel cover and disconnect wiring from connection block. Pull 7 conductor cable out of strain relief.

- Remove cable reel from mounting brackets.

- Remove damaged length cable, which is mounted to the slip rings in the cable reel, from slipring connection.

- On the back side of the cable reel, open the strain relief attached to the axle in the center of the drum. Pull existing length cable out of the cable reel.

- Pull new length cable through the hole, pipe and strain relief and push it through the axle of the reeling drum. Tighten strain relief to ensure sealing.

- Reconnect the length cable to the slipring.

- Remount cable reel to the boom.

- Turn reeling drum clockwise to spool the new cable neatly onto the drum.

- Set preload on cable reel by turning the drum counter-clockwise 5 to 8 turns.

- Wrap the new length cable around the boom tip anchor pin (4 or 5 wraps) and secure with tie wraps. Leave enough length cable to connect into the boom tip junction box.

- Connect the length cable into the boom tip junction box.

- Reset length potentiometer in length angle transducer (screw is located in center of white gear); with boom fully retracted, turn potentiometer carefully counter-clockwise until it stops. Recheck length and angle display.

68 508 06 0001 or 068-508-060-001 PAT Hirschmann LWG508/01 cable reel with length and angle transmission.

PAT Hirschmann LWG 508: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip.

PAT Hirschmann LWG508 ID Tag

A reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.

Hirschmann LWG 508 Cable Reel Schematic

PAT Hirschmann LWG508 Information

The Length-Angle Transducer: The length-angle sensor (LWG) is a combination of two transducers in one box, fitted at the base section of the boom. It measures the length and the angle of the boom as well as transmitting the A2B signal from the boom tip.

A reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG. The angle transducer is fitted in a small box filled with oil. A pendulum drives the axle of the angle potentiometer.

- The power supply voltage for both is -5.00V

- The output signal for the length transducer is: -0.500V up to -4.500V

- The output signal for the angle transducer is: -1.875V up to -3.125V

LWG 508 Length Adjustment: Ensure that the length cable tension is correct with fully retracted boom by turning the cable reel 5 to 8 turns counterclockwise. Then remove cover form LWG and adjust counterclockwise the potentiometer to end stop.

PAT Hirschmann LWG 508 Length Cable Replacement

- Cut old cable at cable drum

- Disconnect damaged length cable from junction box at the boom nose.

- Open cable reel cover and disconnect wiring from connection block. Pull 7 conductor cable out of strain relief.

- Remove cable reel from mounting brackets.

- Remove damaged length cable, which is mounted to the slip rings in the cable reel, from slipring connection.

- On the back side of the cable reel, open the strain relief attached to the axle in the center of the drum. Pull existing length cable out of the cable reel.

- Pull new length cable through the hole, pipe and strain relief and push it through the axle of the reeling drum. Tighten strain relief to ensure sealing.

- Reconnect the length cable to the slipring.

- Remount cable reel to the boom.

- Turn reeling drum clockwise to spool the new cable neatly onto the drum.

- Set preload on cable reel by turning the drum counter-clockwise 5 to 8 turns.

- Wrap the new length cable around the boom tip anchor pin (4 or 5 wraps) and secure with tie wraps. Leave enough length cable to connect into the boom tip junction box.

- Connect the length cable into the boom tip junction box.

- Reset length potentiometer in length angle transducer (screw is located in center of white gear); with boom fully retracted, turn potentiometer carefully counter-clockwise until it stops. Recheck length and angle display.

Have a Question?

The BTS Parts Team is always available to answer any questions you may have. Please feel free to leave a message and we will reply within 24 hours.

4737 North Ocean Drive

Suite 206

Fort Lauderdale FL 33308